Request a VEC Site Evaluation

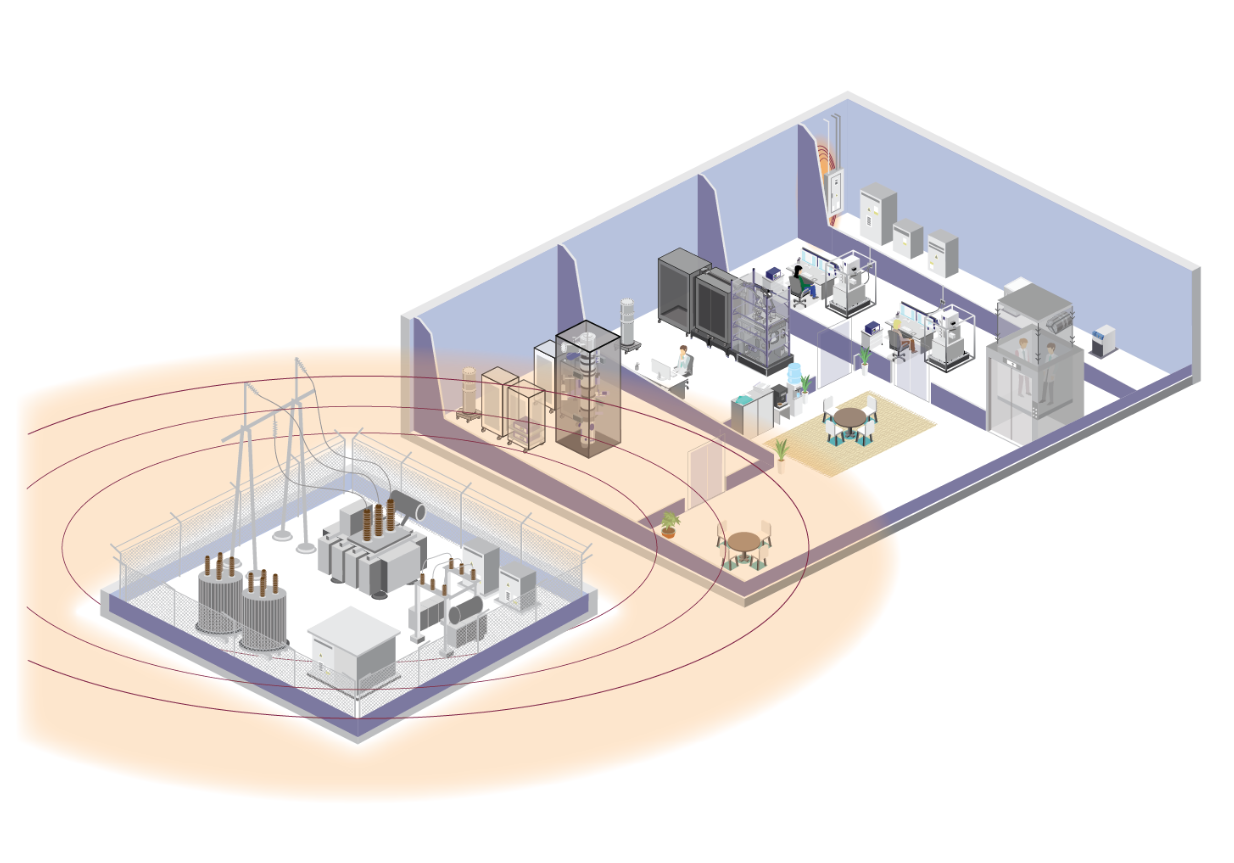

Ensure your facilities meet vibration, acoustic noise, magnetic field, and floor stiffness requirements for precision instrumentation.

The Site Evaluation Process

Site evaluations have many complexities, including multiple location options, numerous pieces of equipment that each has a unique specification, and workflow and administrative considerations. It is essential to follow a defined process to ensure that all required data is collected, and no critical requirements are missed. Below is a little more about what that process looks like on your site.

Identify

Requirements

1

Develop Data

Collection Plan

2

Baseline Data

Collection

3

Source

Identification

4

Remediation &

Solutions

5

Identify Requirements

We first conduct a project briefing to verify we understand your goals, scope, current equipment, future equipment, and budgetary considerations.

Identify Requirements

We first conduct a project briefing to verify we understand your goals, scope, current equipment, future equipment, and budgetary considerations.

Develop Data Collection Plan

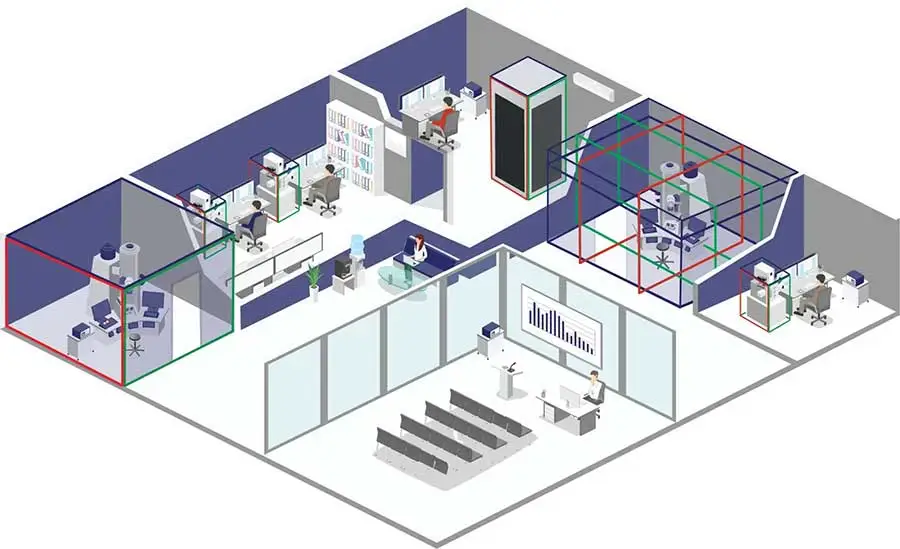

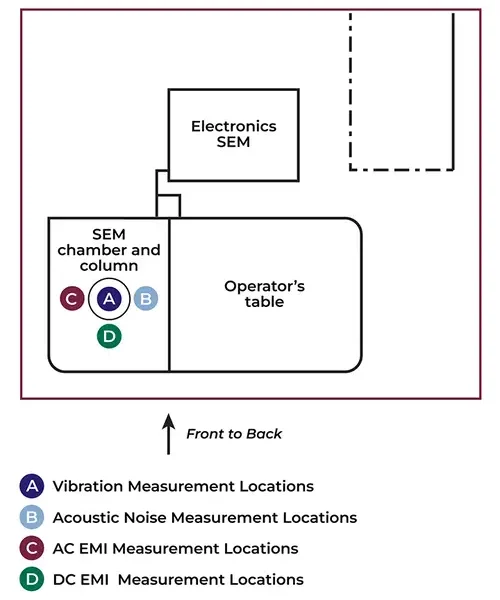

We collaborate with you to develop a data collection plan based on the identified requirements to ensure that we provide you with the best-in-class data needed to make informed decisions. In the data collection plan, we will determine the best strategies to identify the optimal location for your equipment. Considerations include the number and location of data points, specifications used, and the time horizon of data collection.

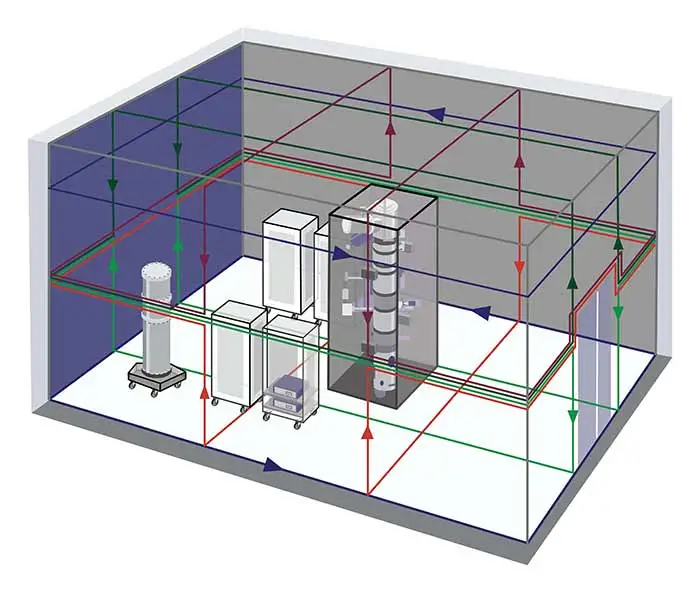

Baseline Data Collection

We record the vibration, acoustic noise, and magnetic field measurements at defined locations depending on requirements. VEC employs a variety of different types of surveys to collect the required data. Our spot surveys provide a baseline understanding of the steady-state factors that impact microscope and tool performance at a single location for a short period in time. Multi-day studies help customers to understand variations throughout the day and differences between days.

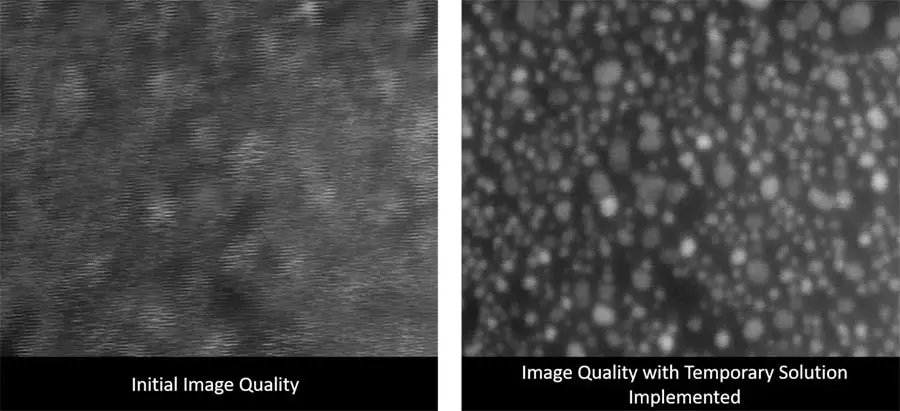

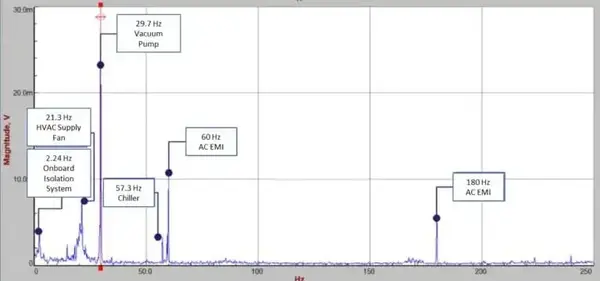

Source Identification

If VEC identifies problems during data collection, we attempt to determine the sources that cause a location to fail the vibration specification or other requirements. For electron microscopes and analytical tools, we correlate an interference in an image or other issues identified during production to known or potential sources of vibration, acoustic noise, and magnetic fields.

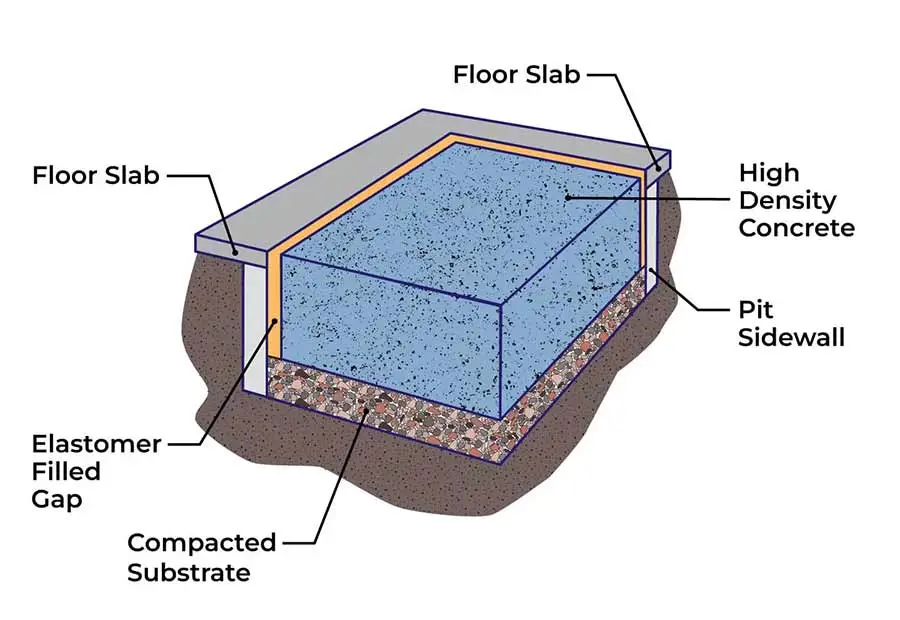

Remediation & Solutions

Next, we will work to correct the problem so that the equipment can achieve optimal performance. We will walk you through the data, explaining the results of your survey along with detailed recommendations specific to your equipment and facility. We strive to provide you with the level of detail that you need to make informed decisions, and we don't finish until we are confident that you understand all the data and recommendations about your site.

The Site Evaluation Process

Site evaluations have many complexities, including multiple location options, numerous pieces of equipment that each has a unique specification, and workflow and administrative considerations. It is essential to follow a defined process to ensure that all required data is collected, and no critical requirements are missed. Below is a little more about what that process looks like on your site.

1

Identify Requirements

We first conduct a project briefing to verify we understand your goals, scope, current equipment, future equipment, and budgetary considerations.

2

Develop Data Collection Plan

We collaborate with you to develop a data collection plan based on the identified requirements to ensure that we provide you with the best-in-class data needed to make informed decisions. In the data collection plan, we will determine the best strategies to identify the optimal location for your equipment. Considerations include the number and location of data points, specifications used, and the time horizon of data collection.

3

Baseline Data Collection

We record the vibration, acoustic noise, and magnetic field measurements at defined locations depending on requirements. VEC employs a variety of different types of surveys to collect the required data. Our spot surveys provide a baseline understanding of the steady-state factors that impact microscope and tool performance at a single location for a short period in time. Multi-day studies help customers to understand variations throughout the day and differences between days.

4

Source Identification

If VEC identifies problems during data collection, we attempt to determine the sources that cause a location to fail the vibration specification or other requirements. For electron microscopes and analytical tools, we correlate an interference in an image or other issues identified during production to known or potential sources of vibration, acoustic noise, and magnetic fields.

5

Remediation and Recommendations

Next, we will work to correct the problem so that the equipment can achieve optimal performance. We will walk you through the data, explaining the results of your survey along with detailed recommendations specific to your equipment and facility. We strive to provide you with the level of detail that you need to make informed decisions, and we don’t finish until we are confident that you understand all the data and recommendations about your site.

Types of Site Evaluations

VEC provides several site surveys and testing services tailored for customers with more specific requirements. We understand that not all customers require a full site evaluation across multiple rooms with multiple specifications, and we help determine the best fit for your needs.

Point Site Survey

VEC conducts point vibration, acoustic noise, magnetic field, and floor stiffness site surveys at the proposed location of a single tool. Measurements take a few hours and provide a good understanding of the steady-state sources impacting a space. Point site surveys are sufficient for most manufacturing and imaging equipment. At the end of the project, you will receive a detailed written report with our findings and recommendations.

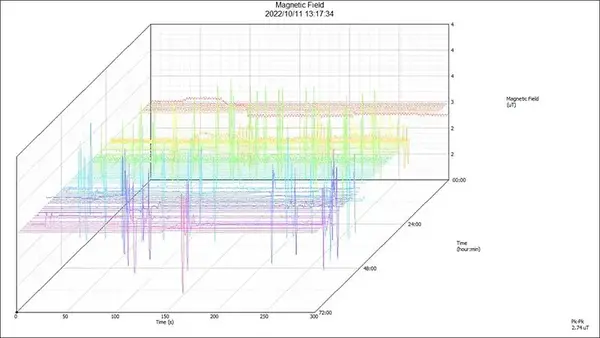

Multi-Day Site Survey

A longer 48-72 hour site survey using the Spicer SC11 Auto Survey System enhances data accuracy by capturing transient vibration, acoustic noise, and magnetic field sources. The SC11 systematically measures at set intervals throughout the survey period, identifying fluctuations in these factors. Particularly beneficial for advanced electron microscopes and tools in dynamic environments, multi-day surveys provide comprehensive insights crucial for optimal performance.

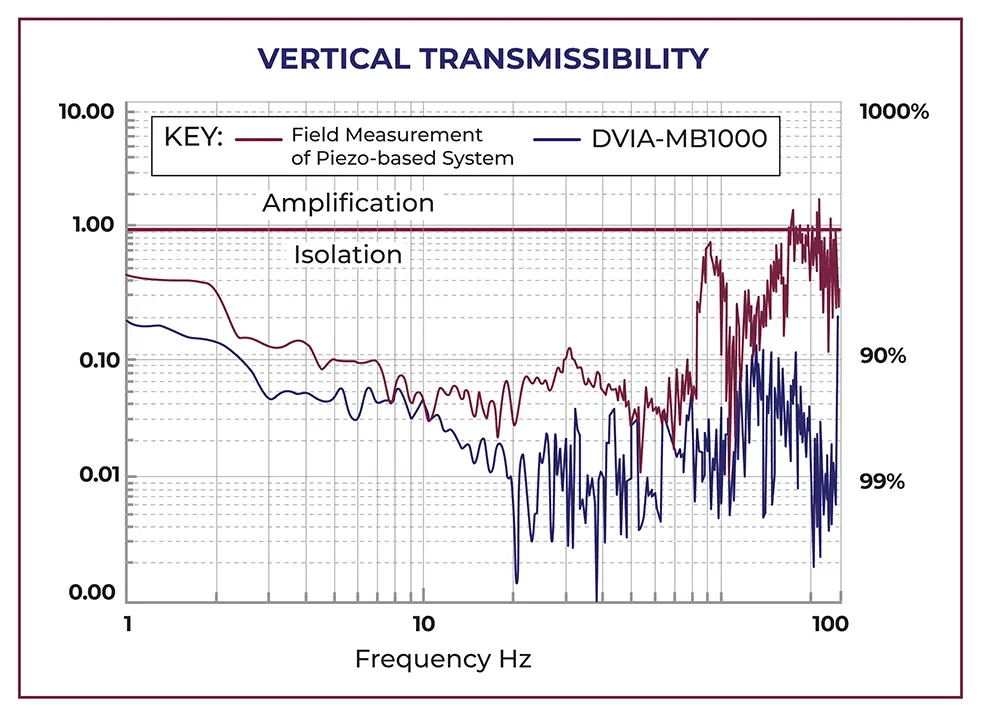

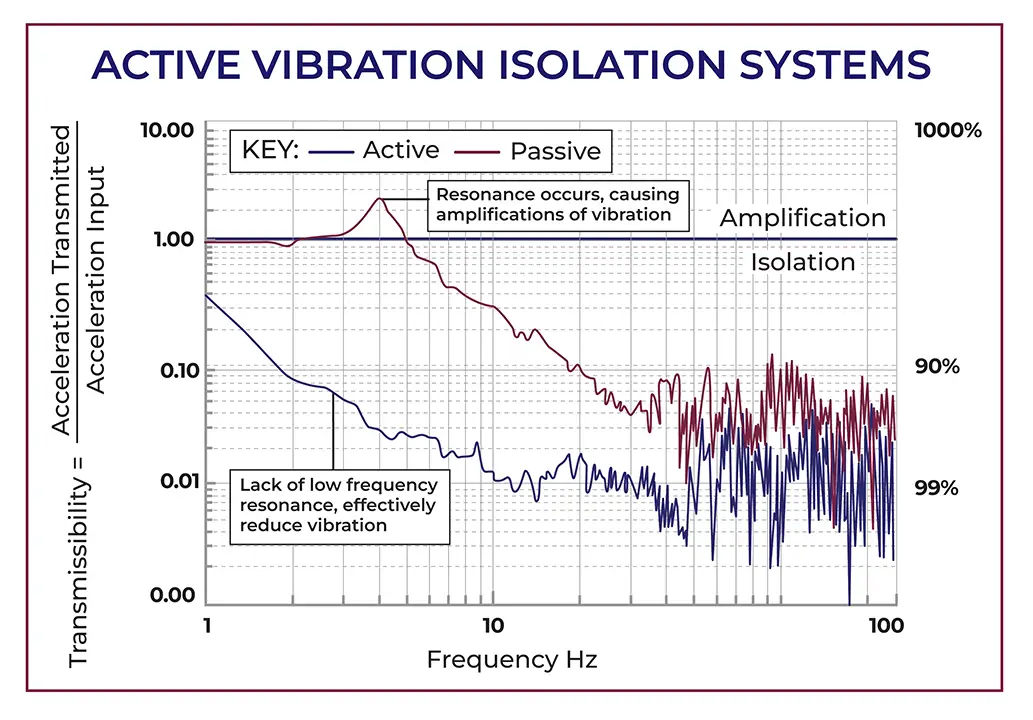

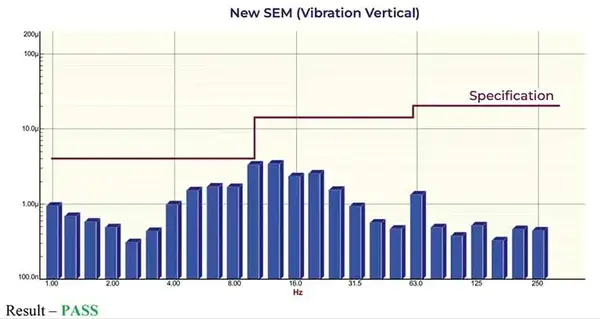

Vibration Survey

VEC can perform a vibration site survey if a tool has specific vibration requirements or the customer is primarily concerned with general facility vibration. VEC can compare the results to the tool's specifications, standard vibration criteria, or VC curves.

Acoustic Noise Survey

VEC conducts detailed acoustic noise surveys in labs and noise-sensitive areas to determine if a facility meets instrument noise specifications. Often, VEC combines acoustic testing with acoustical modeling to predict planned mechanical or HVAC equipment noise, minimize reverberant noise, and ensure planned mechanical equipment complies with local codes and ordinances.

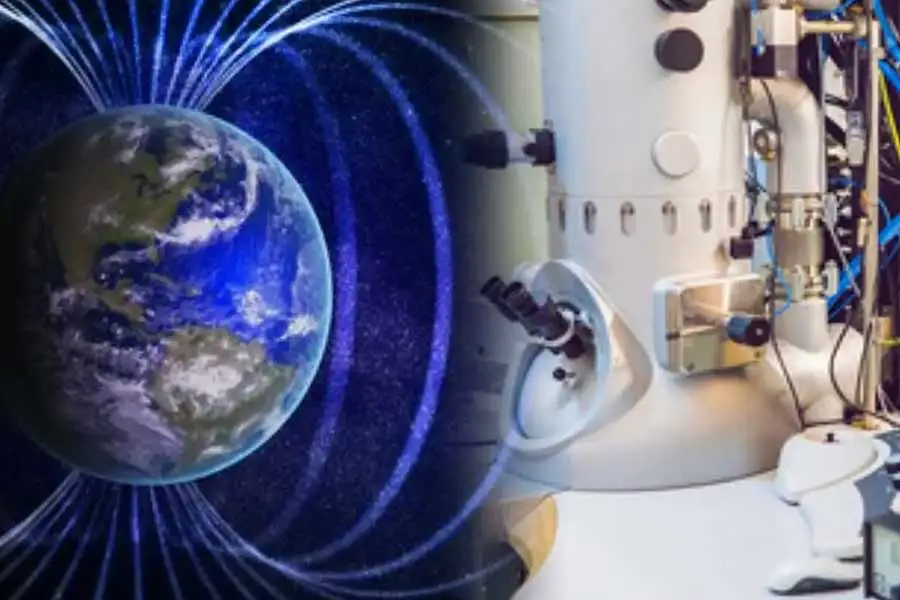

Electro-Magnetic Interference Site Survey

Magnetic fields can degrade the performance of electron microscopes and e-beam lithography tools. VEC conducts magnetic field testing per customer needs, measuring field levels, identifying sources, and offering necessary mitigation recommendations.

Advanced Image Problem Solving – Spot Mode Video

VEC uses raw detector data for diagnosis when electron microscopes encounter image issues. Through a technique called Spot Mode Video, VEC correlates the data directly to environmental sources, effectively diagnosing complex image problems and determining if they are internal or external to the microscope.