Active Vibration Isolation Products

Ultra-High-Resolution Electron Microscopes

Outstanding Performance, Optimized for SEMs

SEMs, FIBs, Dual Beams, & Analytical Equipment

SEMs, FIBs, Dual Beams, & Analytical Equipment

Precision Instruments on Optical Tables

Desktop for Precision Microscopes & Instruments

Precision Tabletop Microscopes & Instruments

Semiconductor, Metrology, & Inspection Tools

Technical Benefits

Customization for Your Tools & Facility

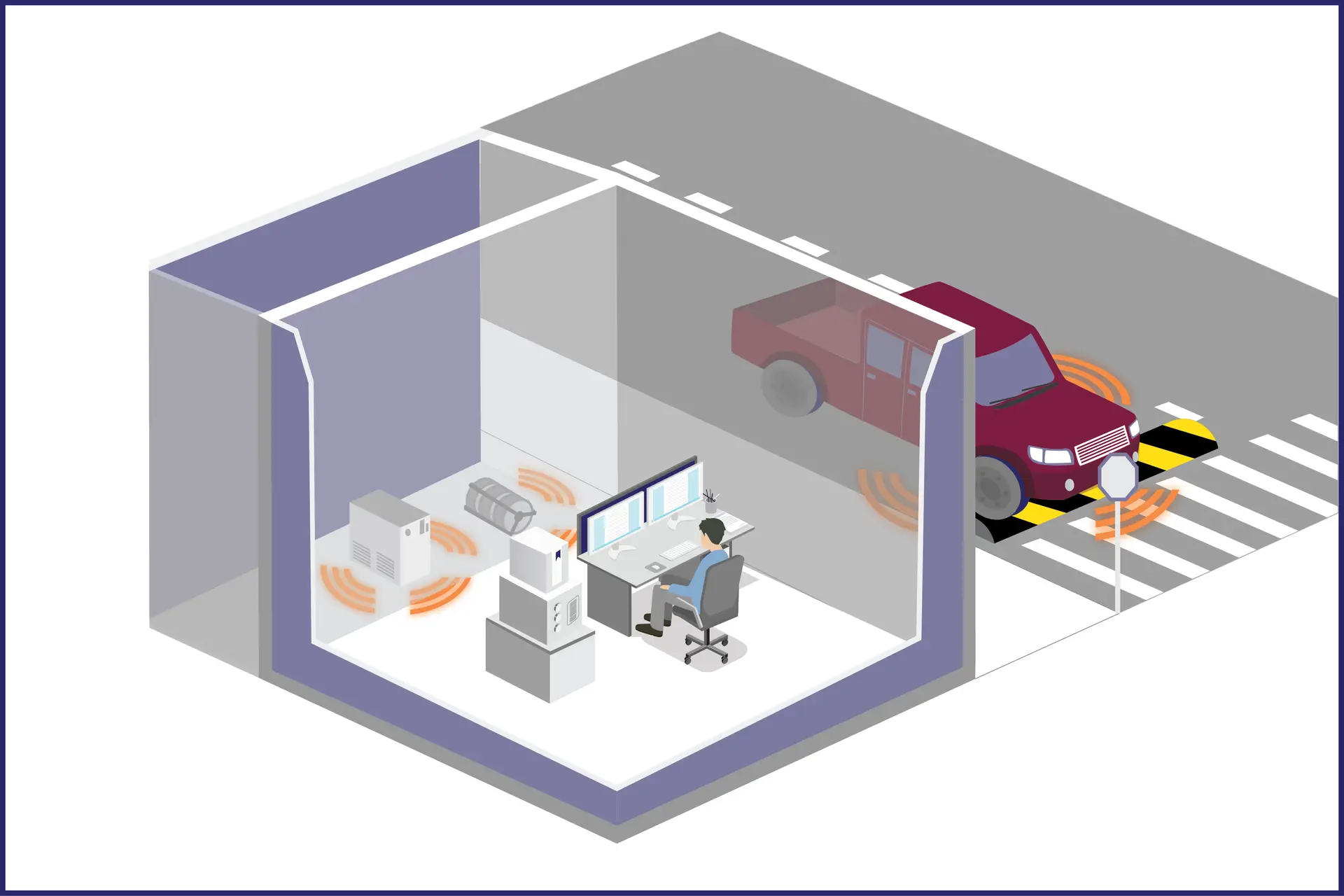

We customize solutions to your unique requirements, considering facility vibration, tool weight, footprint, center of mass, and internal operations. After reviewing the data, we will design a tailored solution, incorporating pedestals for raised floors, seismic restraints, and non-isolated platforms for ancillary equipment and enclosures as needed.

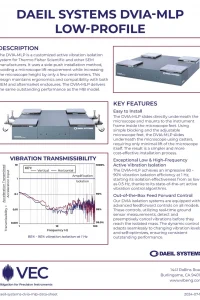

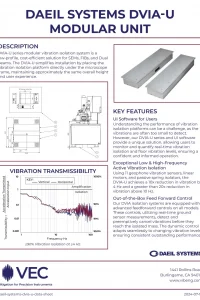

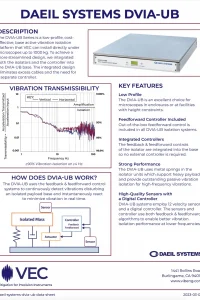

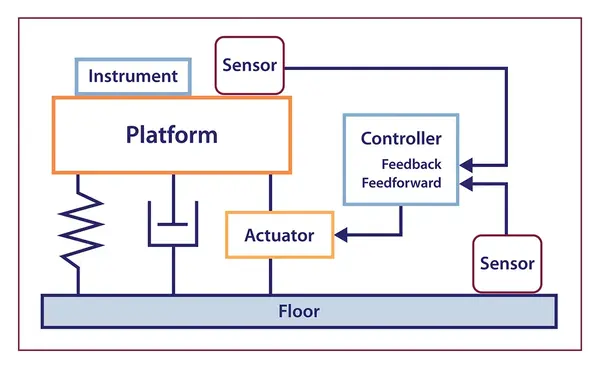

Out-of-the-Box Feed Forward Control

DVIA active isolation systems come equipped with feedforward controls on all models. These controls use real-time ground sensor measurements to detect and preemptively cancel vibrations before reaching the isolated mass. The dynamic control adapts seamlessly to changing vibration levels and self-optimizes, ensuring consistent outstanding performance.

More Resistant to Variations in Floor Stiffness

Feedforward controls and passive component design depend less on floor stiffness than piezoelectric systems. As a result, VEC can install a DVIA active vibration isolation system on any building floor and most floor surfaces, unlike other options on the market.

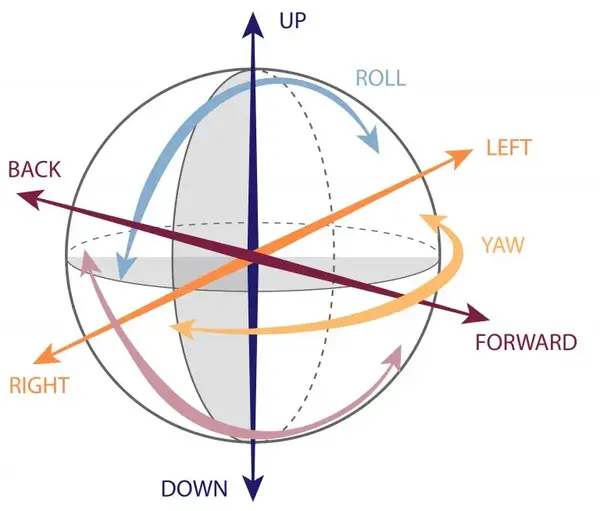

Active Vibration Isolation in All Six Degrees of Freedom

All DVIA Systems control vibrations in three translational degrees of motion (X, Y, and Z) and three rotational degrees of motion (pitch, roll, and yaw.)

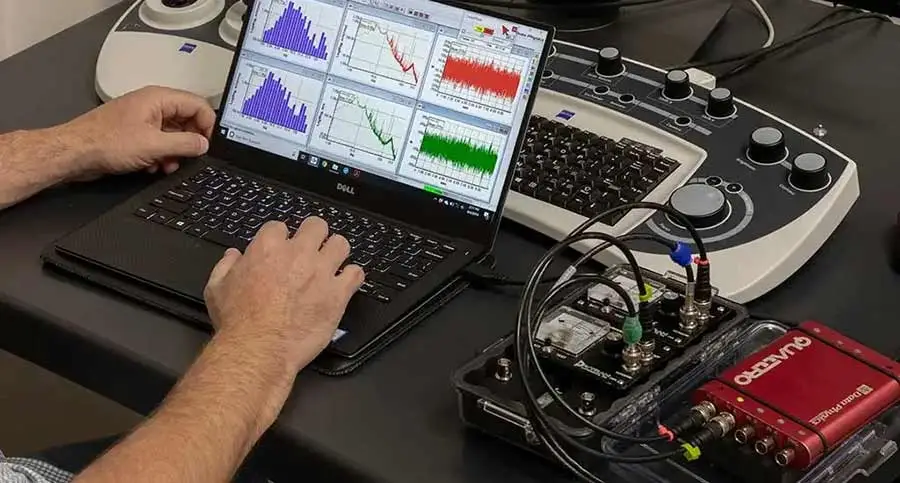

On-Site Optimization for Better Performance

Vibration levels vary based on location, sources, and other factors. Our engineer optimizes the feedback and feedforward control systems for optimal vibration isolation performance based on instrument size, weight, and your site's vibration characteristics.

Turnkey

Solutions

Production

Selection

Design

Production

Stakeholder

Coordination

Installation

Support

Turnkey Solutions

VEC delivers turnkey solutions for vibration isolation, magnetic field cancellation, and acoustic abatement for your laboratory. You get expert guidance in product selection, transparent design, on-site installation, and post-sale support for sustained performance with us.

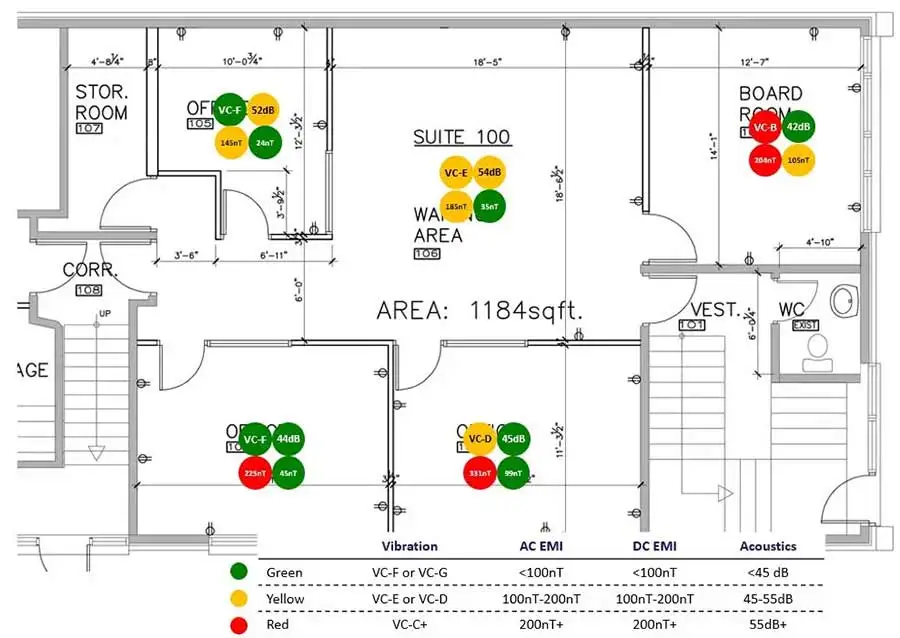

Product Selection

VEC reviews instrument specifications, site testing data, and facility layout to select the product most suitable for your requirements.

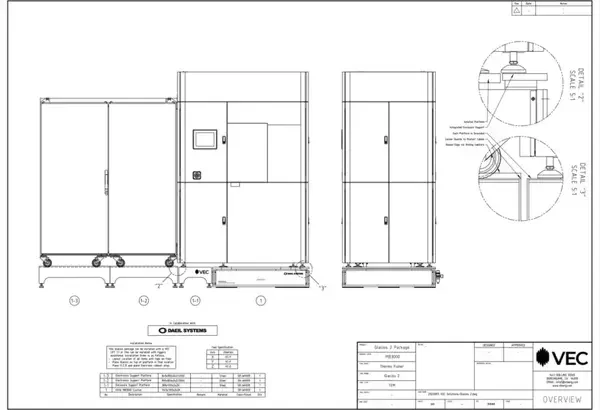

Design

VEC provides design documents based on instrument footprint, product details, and project drawings to communicate the proposed solution before purchase. Seismic calculations and stamped structural drawings are available as needed.

Production

VEC ensures production accuracy based on the design and will keep project members abreast of timelines and delivery details.

Stakeholder Coordination

VEC strives to clearly coordinate with the many project stakeholders, including architects, facilities, contractors, and equipment manufacturers.

Installation

VEC engineers will provide on-site installation services to ensure your systems' proper installation and performance. VEC provides installation reports documenting the installation and system performance.

Support

VEC stands behind its products and performance beyond the sale and installation, and engineers are available for support as needed.

Turnkey Solutions

VEC delivers turnkey solutions for vibration isolation, magnetic field cancellation, and acoustic abatement for your laboratory. You get expert guidance in product selection, transparent design, on-site installation, and post-sale support for sustained performance with us.

Product Selection

VEC reviews instrument specifications, site testing data, and facility layout to select the product most suitable for your requirements.

Design

VEC provides design documents based on instrument footprint, product details, and project drawings to communicate the proposed solution before purchase. Seismic calculations and stamped structural drawings are available as needed.

Production

VEC ensures production accuracy based on the design and will keep project members abreast of timelines and delivery details.

Stakeholder Coordination

VEC strives to clearly coordinate with the many project stakeholders, including architects, facilities, contractors, and equipment manufacturers.

Installation

VEC engineers will provide on-site installation services to ensure your systems' proper installation and performance. VEC provides installation reports documenting the installation and system performance.

Support

VEC stands behind its products and performance beyond the sale and installation, and engineers are available for support as needed.

Downloads & Videos

Industry Leading Active Vibration Isolation

Technical Blogs & Case Studies

Understanding Vibration Isolation for Electron Microscopes and Precision Instruments

Electron Microscopes on High Floors: Why VEC’s Daeil DVIA Systems Are the Only Vibration Isolation Option

Vibration Isolation for Cryo-TEM: Over 90% Measured Reduction at 2 Hz

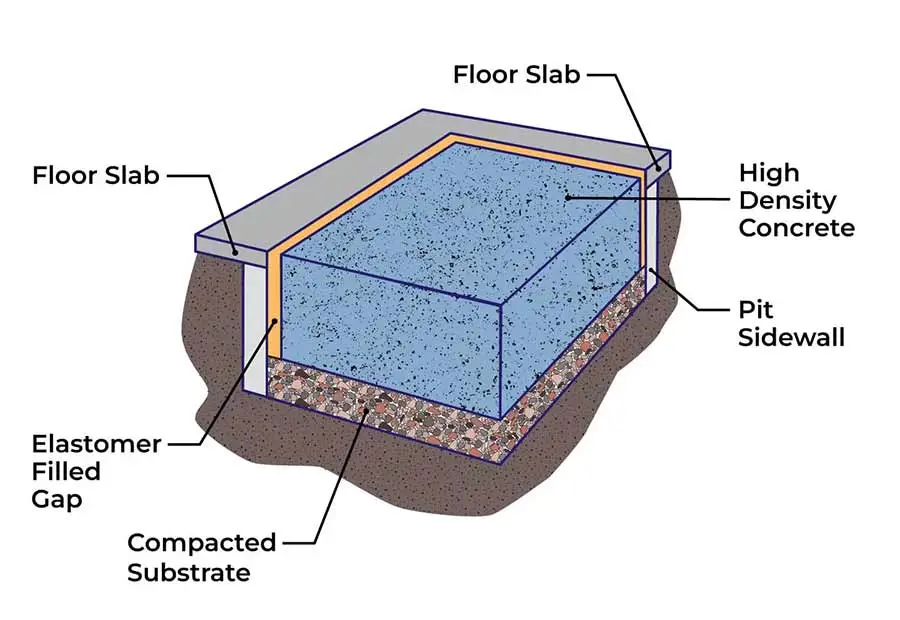

Isolated Slabs: Do they work? What does the data say?

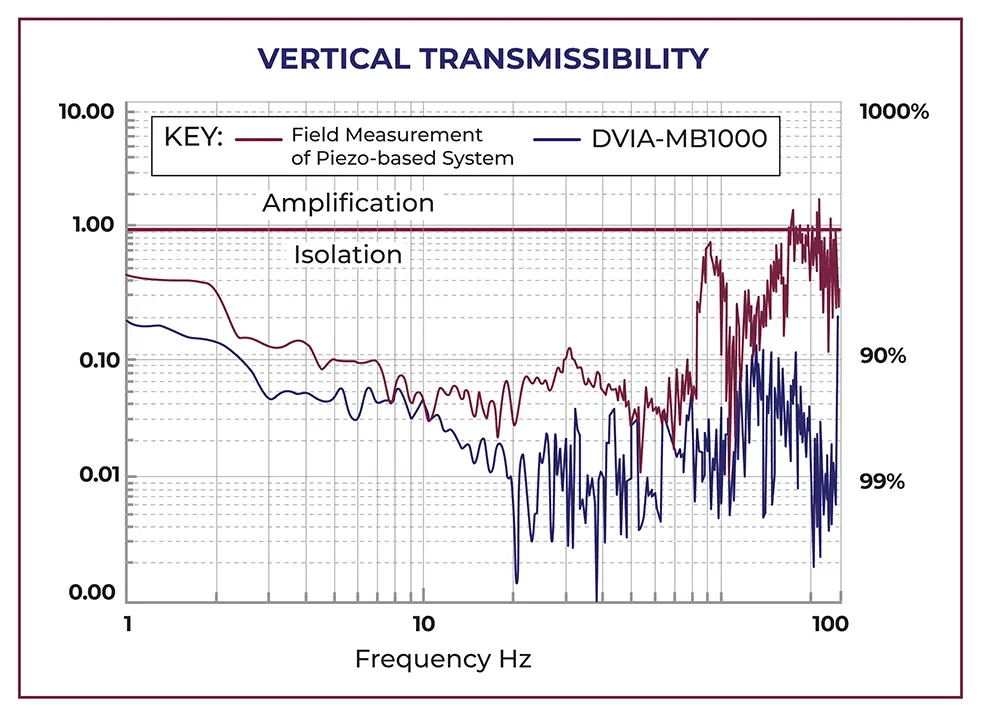

DVIA-M vs Piezoelectric Vibration Isolation Systems. Which is King?

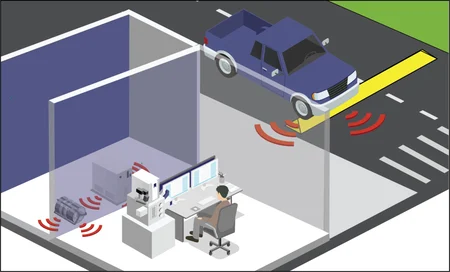

Electron Microscope Vibration: An Increasing Issue in Today’s Laboratories

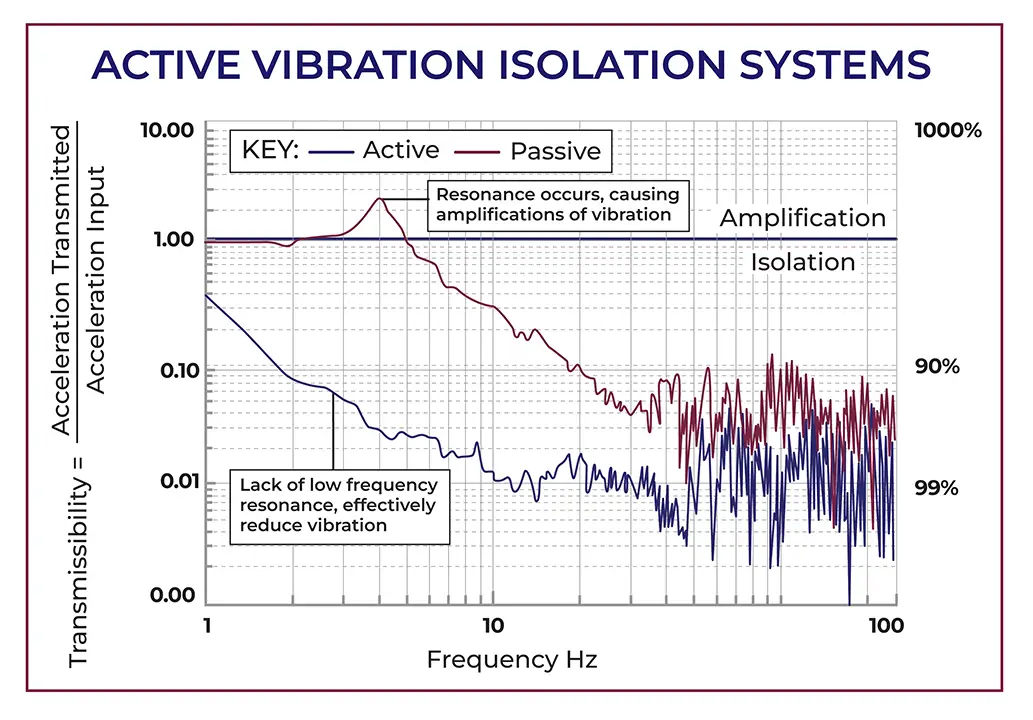

Active vs. Passive Vibration Isolation

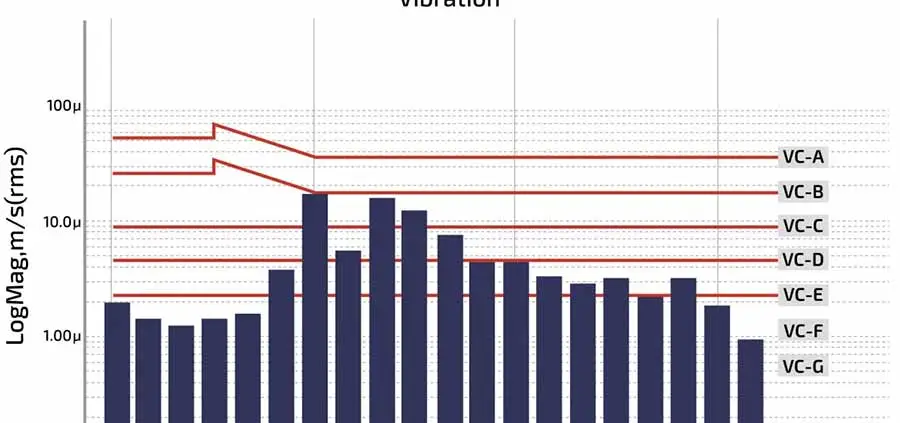

What are VC-Curves, why are they useful, and how are they relevant?

Overcoming Microscopy Interference When You Can’t Find the Source of the Problem

Understanding and Mitigating Vibration In Your Facility

Site Survey: Why Use a Third-Party?

Cutting Edge Semiconductor Facility In An Old Building On A High Floor?

Cleanroom Site Evaluation – An Avoided Disaster

Reducing Vibration from Mechanical Equipment in an Electron Microscopy Lab

Let’s get in touch