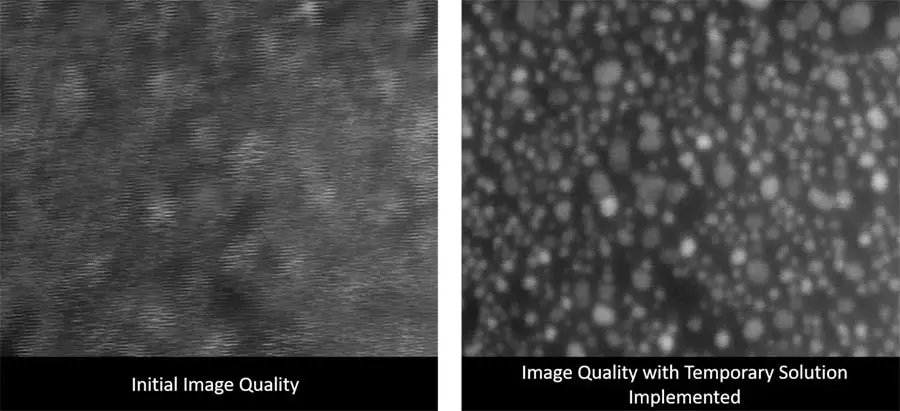

A bioengineering company had an image disturbance on a scanning electron microscope (SEM). The company retained VEC to determine the cause of the image disturbance and either implement or recommend a solution. Using Spot Mode Video, VEC determined that an improperly mounted muffin fan located on the back panel of the SEM was the source of the disturbance. VEC implemented a temporary solution on site and provided the company with the necessary data to resolve the problem with the manufacturer. The temporary solution implemented by VEC significantly improved image quality and provided a clear path towards a permanent solution.

A bioengineering company was experiencing image disturbance on their SEM. The company was unsure of the source of the disturbance, but suspected that the problem was in the laboratory space. The microscope owner was worried that the solution would be costly and/or difficult to implement. Without remediation, the SEM would not be able to produce useful images, therefore, limiting the laboratories ability to operate effectively.

VEC used Spot Mode Video to identify the frequency of disturbance resulting in poor image quality on the SEM. Using the data collected, VEC determined that the source of the disturbance was not caused by vibration, acoustic noise, or magnetic field in the laboratory space. While inspecting the microscope for vibration, the VEC engineer identified an improperly mounted muffin fan as the source of the disturbance. The VEC engineer implemented a temporary solution on-site dramatically improving image quality. In addition, VEC provided the client with a written report so the manufacturer fixes the problem.

The client was able to quickly resume normal activities and use the SEM and laboratory space at maximum capacity. In addition, the temporary solution implemented was simple and inexpensive. Finally, the written report enabled the client to go to the manufacturer and have a permanent fix implemented.

Contact our expert team at VEC to get started.