Understanding and Mitigating Vibration In Your Facility

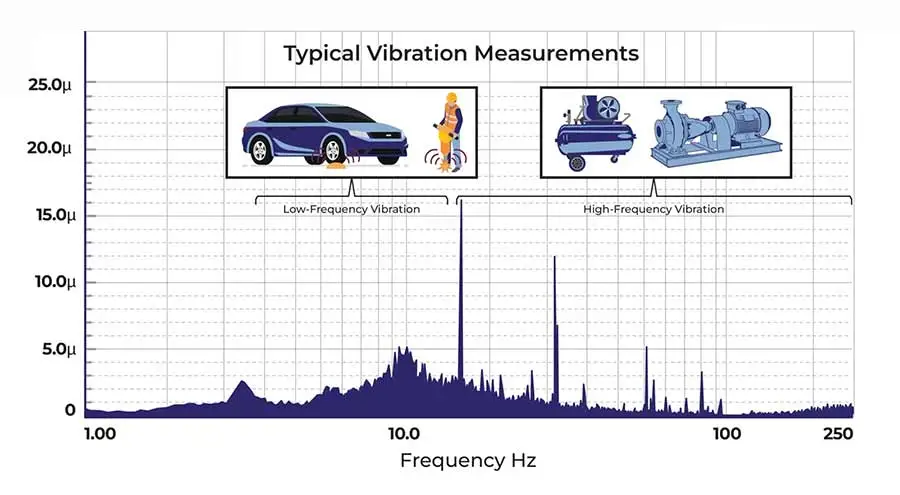

Low-frequency and high-frequency vibration both have a significant impact on electron microscopy laboratories and high-tech manufacturing facilities. These two types of vibration stem from different causes and the strategy for mitigating vibration for each is also different. Vibration Engineering Consultants (VEC) can help you quantify and identify the vibration in your facility and work with you to develop remediation strategies based on your unique requirements.

About Low-Frequency Vibration

Sources outside your facility typically cause Low-frequency vibration. Large impulses excite low-frequency ground resonances that are dependent on the soil conditions within your area. These resonances are usually from 3-20 Hz. Some examples of the sources of impulses include traffic, speed bumps, construction, or trains. Building movement on higher floors is also a source of low-frequency vibration.

Sources of low-frequency vibrations are typically stable over time unless some dramatic change in the infrastructure occurs, or a construction project begins immediately next door. These impulses travel farther and have more energy than high-frequency vibration sources.

Vibration will most severely impact your equipment if it corresponds with the resonance of the tool itself. Think of a child on a swing. If you’re pushing at the same frequency that the swing naturally oscillates, the amplitude increases. The natural oscillation frequency, or natrual frequency, depends on the length of the swing from the pivot point to the child. Pushing the swing at the natural frequency may be fun for the child, but for a machine in the lab, exciting the machine’s natural resonances often degrades its performance.

Low-frequency and high-frequency vibration are caused by different categorical sources and require different approaches to mitigate

Mitigating Low-Frequency Vibrations

A lab or high-tech manufacturing facility only has one option to reduce this type of vibration – an active vibration isolation system. In these systems, feedback and feedforward control systems use integrated sensors and actuators to isolate equipment from vibration. Sensors detect incoming vibration, and a controller sends signals to the actuators that generate equal and opposite force to negate the impact of outside vibration on your equipment.

Although the best systems are very effective at mitigating vibration, they can be costly. Installing active isolation systems in an entire lab can often add hundreds of thousands or even millions of dollars to the cost of your facility.

In an ideal situation, it is best to test and monitor vibration before moving into a new facility. Conducting a thorough site evaluation or installing vibration monitors can prevent expensive mistakes. It’s similar to inspecting for mold or other dangerous chemicals in a home before you move in. Sometimes the cost of the repairs can sway the decision to purchase. However, moving facilities is often not an option. In these situations, there is no way other than an active isolation system to mitigate the low-frequency problem, particularly for vibration source located off of your property. Selecting a facility site that does not have a low-frequency vibration problem will pay off in the long term.

This problem will be more prevalent, especially as instrument resolution increases, critical dimensions shrink, and as microscopes and high-tech lab equipment become increasingly sensitive to low-frequency vibration.

About High-Frequency Vibrations

The impacts and the vibration mitigation are quite different with high-frequency vibrations. High-frequency vibration sources usually originate inside your facility. Some examples might include pumps, chillers, fans, or HVAC systems. The rotating frequencies of these objects may result in vibrations that disrupt tool performance. High-frequency vibrations often change and intensify over time. Because these sources are typically internal to your facility, they are in closer proximity to the tool location and often occur between 20 and 200 Hz.

Mitigating High-Frequency Vibrations

The oscillating current in AC magnetic fields causes the beam to move back and forth at either 50 or 60 Hz, depending on where you are in the world. AC EMI Interference causes a jagged appearance around the outside of an image, typically referred to as flagging or sawtoothing, and rendering the image unusable.

High-frequency vibrations often can be mitigated with low-cost isolators, thoughtful equipment placement, and by keeping machinery in good working order. These solutions are often more effective than active vibration isolation systems, which manufacturers optimize to mitigate low-frequency vibrations. Many active vibration isolation systems do not mitigate vibration at higher frequencies starting at ~50 Hz. Most sources of mechanical vibration operate within this elevated range.

Since high-frequency vibrations typically change and increase over time, vibration monitoring is an effective and cost-efficient way to prevent vibration problems. The ability to mitigate vibration is strengthened by data and your ability to understand the problem. Monitoring can give you the data that you need to relocate affected equipment, or initially place it in an area that’s not impacted by vibration. Your facility is likely evolving and accumulating new pieces of equipment over time. Understanding the environment can help you get the most out of your investment. By deploying custom-designed vibration monitors in your facility, such as the SC-28 system, you can anticipate problems before they ever impact your equipment.

Use Data in Mitigating Vibration

Because not all vibrations are the same, the way they influence your equipment will differ as well. Hiring an expert like VEC can help you to quantify the data so you can make more informed decisions.

We can help with:

- Vibration Testing – Site evaluations can help you determine where to place equipment and evaluate potential sites before move-in or purchase. These serve as a snapshot of current vibration levels at your facility or a proposed site.

- Vibration Monitoring – Our SC-28 system is specifically designed to monitor vibration for high-tech and microscopy facilities. It can help with both site evaluations and preventing vibration from reaching problematic levels over time.

- Assessing Vibration Mitigation Options – We can help you determine which strategy for mitigating vibration is right for you and your facility.

- Active Vibration Isolation Platform – VEC is a proud distributor of Daeil Systems’ active vibration isolation products. VEC can help select and design an active vibration isolation system to meet your unique requirements.

Vibration can be costly and overwhelming when discovered nearby or inside your building. We will help you develop a practical strategy for mitigating vibration, and making sure it does not interfere with your current operations. If you’d like to discuss your next project, contact us today!