Electron Microscope Vibration: An Increasing Issue in Today’s Laboratories

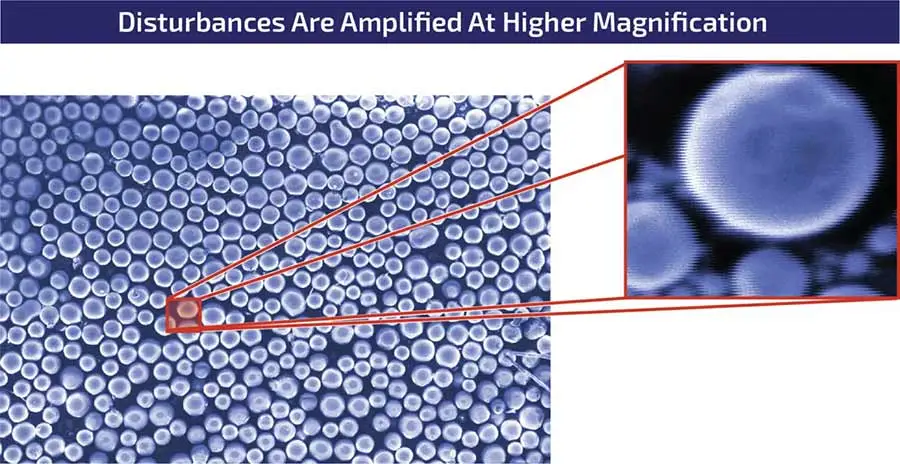

Electron microscope vibration is an increasing concern in modern laboratories because of improving resolution and extended duration imaging. At higher resolution, external vibrations have a proportionally greater impact on image quality. Also, extended duration imaging and 3D reconstructions cause image quality to be more susceptible to incremental sources of vibration

Owners need to bear this increased sensitivity to vibration in mind as they determine where to install a tool and design their laboratory. Monitoring and a detailed site survey can help them gain essential insights on their most sensitive equipment. Even in the best location at your facility, active vibration isolation may ultimately be necessary in some circumstances.

In addition to vibration, electron microscopes are becoming increasingly sensitive to magnetic fields and acoustic noise for many of the same reasons. However, this article focuses on the impact of mechanical vibration on electron microscopes and provides approaches to mitigate its effect.

The Increasing Power of Today’s Electron Microscopes and Equipment

Modern electron microscopes are more powerful than ever before, offering increased resolution and enhanced capabilities. While this is exciting news, laboratories need to remain on guard for vibration sources that can impact electron microscope performance.

In an attempt to reduce the impact of vibration, some manufacturers are integrating advanced vibration isolation systems. These isolation systems are onboard the microscope and perform better than the passive systems used in the past. However, at high resolution, these built-in vibration isolation systems do not compensate for the vibration in many laboratories. The trend toward higher levels of vibration sensitivity within this equipment is continuing. To achieve the best performance from your electron microscope, owners should address vibration issues early on.

Longer Imaging and 3D Reconstruction Pose New Obstacles

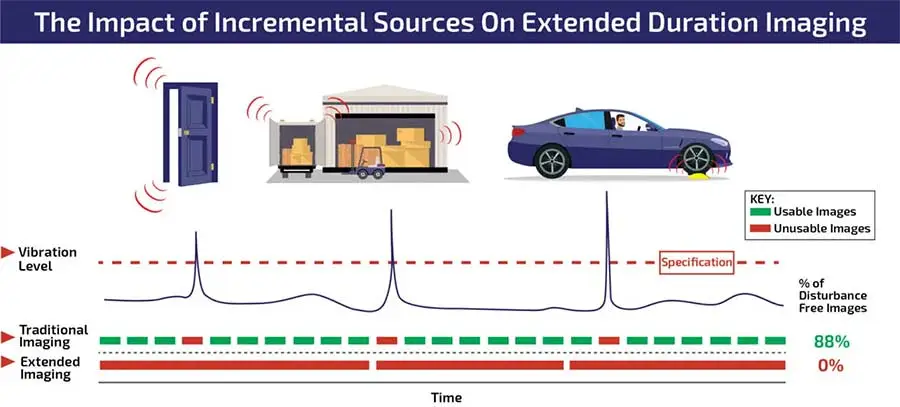

In the past, all electron microscopes captured an image in a single scan. The microscope completed the image in less than a minute. For this type of imaging, a passing train or a door slamming might be inconvenient, but users could easily overcome these transient sources by retaking the image. Because a scan only takes about a minute, the cost of retaking the image is only a minute of the user’s time.

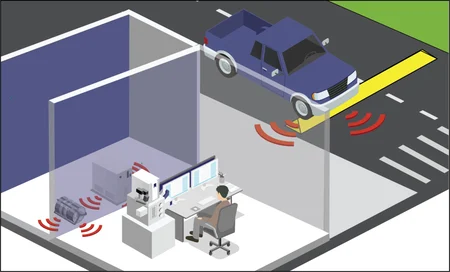

Today’s electron microscopes perform extended duration imaging for 3D reconstructions, producing fantastic images and data that was previously impossible on older systems. But creating these images takes many hours or even days. Because of the increased time commitment for a single image, the impact of incremental vibration sources such as passing vehicles, doors slamming, or equipment turning on and off is costly in both time and resources.

If an intermittent event occurs during extended imaging or a 3D reconstruction, the image could be worthless, and the hours or days spent setting up and imaging wasted. Therefore, vibration problems should be identified and mitigated before the microscope is installed.

The Importance of Site Evaluations

One way to address these problems is to monitor and survey the site before determining where to place the instrument. With tighter vibration specifications on the equipment, the need to do a pre-installation site survey is imperative.

Ideally, users should evaluate multiple locations and select the best site because remediation is expensive. Users should monitor potential locations in the laboratory using the Quantridge platform. Monitoring sites over weeks or months allows users to determine the best location for their microscope more easily. Lab managers should also carefully consider where to place essential equipment during the initial setup process.

Another option is to conduct a site evaluation. If any known intermittent vibration sources are nearby, a detailed survey will quantify these to ensure compliance. Intermittent sources can include things like stairs, doors, train traffic, among other sources of vibration. These site evaluations increase in importance when the proposed microscope performs longer duration imaging because intermittent vibration events prove costly.

Focus on Laboratory Setup

Lab managers need to prioritize ensuring the proper setup and layout of their equipment. Laboratory setup and design includes making sure that any vibrating equipment is correctly isolated and an appropriate distance from the microscope.

Once the laboratory is complete, monitoring the microscope post-installation ensures that changes in the laboratory or activity in adjacent laboratories do not interfere with the new lab equipment.

When Vibration Isolation Makes Sense

Low-frequency vibration, particularly intermittent low-frequency vibration, is problematic and nearly impossible to mitigate. In these cases, users require an active vibration isolation platform such as the Daiel DVIA-MB series.

When evaluating multiple locations, users should balance the cost of the vibration isolation platform with the other operational considerations of the site. These considerations can include workflow requirements, available square footage, and future expansion plans.

Conclusion: Reduce or Eliminate Electron Microscope Vibration

While today’s electron microscopes are increasingly powerful pieces of equipment, that enhanced power does come with a trade-off. Users need to pay more attention to both absolute vibration levels and intermittent vibration sources.

Monitoring pre and post-installation provides continuous data on the vibration levels on-site, as well as immediately flagging new sources of vibration that is impacting the space.

If monitoring is not possible because of time constraints, a detailed site survey that evaluates multiple locations is recommended. It allows laboratories to select an area that is ideal as opposed to forcing the microscope to work in a predetermined space. Some locations will require an active vibration isolation platform, primarily to mitigate low-frequency vibration.

When you can adequately manage vibration within your laboratory, you’ll be able to leverage the full capabilities of your equipment. If you have any questions or would like to talk about your laboratory, contact us today!