A growing semiconductor company in the USA is evaluating a new location for its cleanroom space. The company wants to ensure that magnetic fields, acoustic noise, and vibration levels will be suitable for their sensitive tools. Vibration Engineering Consultants (VEC) completed a thorough evaluation, during various times of the day, to determine if the proposed space was conducive to the company’s short-term and long-term goals. Using the data collected, VEC determined that the proposed location was not suitable for sensitive tools and equipment. This is due to the proximity to a local airport with commercial traffic and power lines adjacent to the location. VEC then worked with the client to assess and validate a suitable new facility for their cleanroom.

A semiconductor company in the USA has outgrown its current clean room and is searching for a new location. The company identified and possible new location but has concerns regarding the suitability for sensitive tools and equipment. The proposed location is surrounded by an airport, commuter traffic, and power lines. Because the company’s tools are sensitive to vibration, magnetic field, and acoustic noise, the company retained VEC to conduct a thorough site evaluation. As the lease was due to be signed in less than two weeks, VEC conducted the testing immediately.

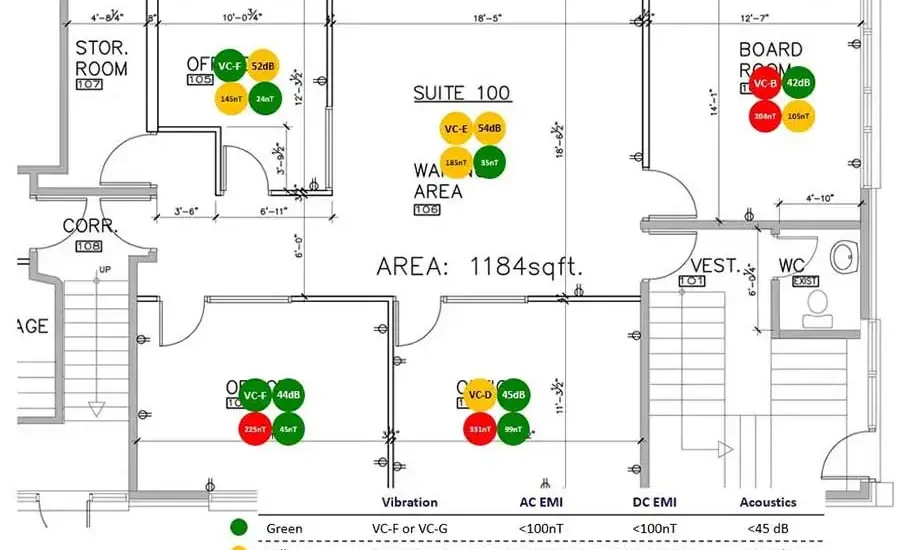

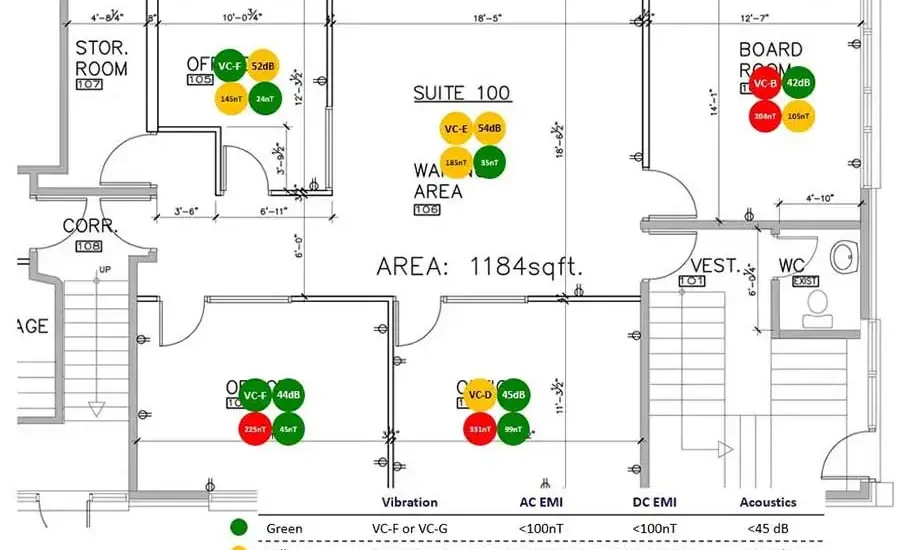

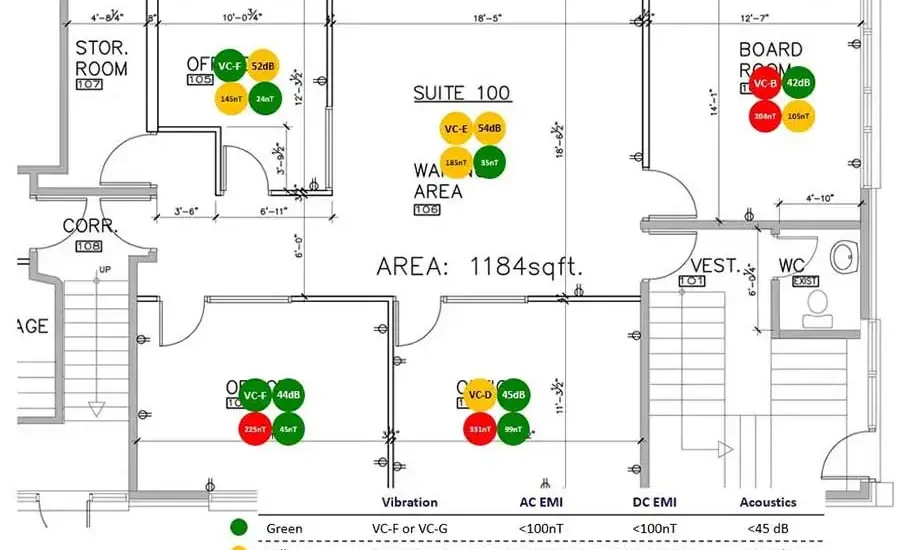

Using calibrated testing equipment, VEC collected baseline vibration, magnetic field and acoustic noise data. Since the company was unsure of the specific specifications for its new tools, VEC leveraged its extensive database to help develop evaluation requirements for the testing. VEC took measurements throughout the day to determine the times when the laboratory space would be most impacted. VEC utilized graphical representations to synthesize the results and provided an analysis with detailed recommendations for the client.

VEC worked with the client to develop the following key insights from the project:

Based on the analysis conducted by VEC, the company decided to evaluate other locations for their new clean room space. VEC collaborated with the company and was able to identify a second location that better met tool requirements. This saved the company wasted time in a facility with vibration, acoustic noise, and magnetic field problems as well as hundreds of thousands of dollars on vibration, acoustic noise, and magnetic field solutions.

Contact our expert team at VEC to get started.