Site Survey: Why Use a Third-Party?

When purchasing or moving a new electron microscope or process tool, customers have a few options when it comes to deciding who should provide their site survey. The original equipment manufacturer (OEM) will often offer the survey, and organizations sometimes attempt to conduct the survey themselves in-house. In this post, we will discuss the benefits of a third-party site survey, why it is an excellent return on a minimal investment, and risks associated using a less experienced provider.

The costs associated with site survey mistakes are often remarkably high. Therefore, using an experienced third-party engineering firm, such as Vibration Engineering Consultants (VEC), to conduct a site survey has tremendous advantages to the customer. VEC conducts dozens of surveys every month across a wide range of environments, tools, and microscopes. We will tell you whether you pass or fail, give you a wide range of associated data, including the source of issues, and provide detailed recommendations about how to remediate identified issues in a cost-efficient manner.

Below are Four Reasons to Go with an Experienced Third-Party Provider for Your Site Survey

Reason One: A Third-Party Site Survey Provides a Broader Scope and More Actionable Information

- Vibration

- Acoustic noise

- DC magnetic fields

- AC magnetic fields

- Stiffness testing

- Electric field

- Lux

Many facilities have multiple tools from multiple manufacturers. An experienced third-party survey provider will take the time to get to know the whole facility to understand what exactly is occurring. An OEM will be looking at a single data point for a unique tool. An independent provider will survey across tool types and compare a single data point against multiple tool specifications.

Going with a third-party provider means that you have an independent surveyor who will help you make informed decisions. They are an objective party in the process, and not tied to the interests of the manufacturer in any way.

When a customer goes with an OEM survey and fails, the manufacturer is no longer liable to meet performance requirements. An experienced third-party provider will offer you the data and direction that you need to regain compliance.

Reason Two: Site Surveys are Complicated, and It’s Easy to Make Mistakes

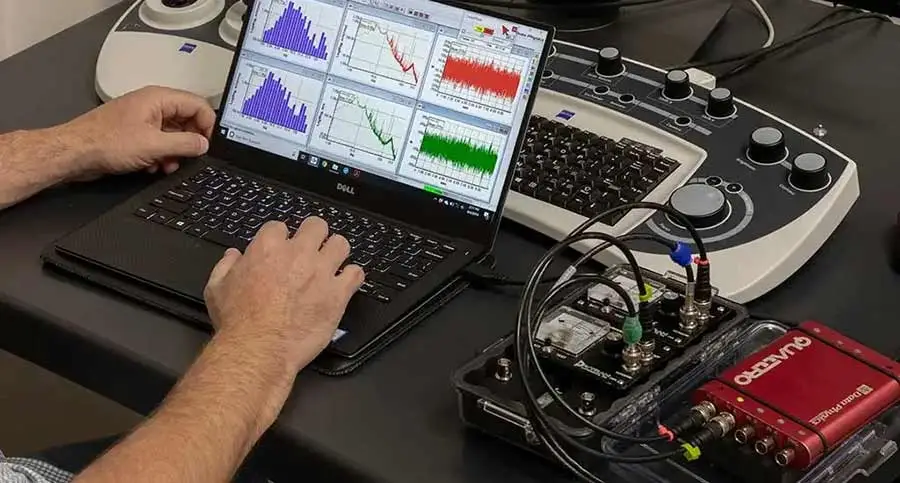

When you conduct a site survey, you are responsible for sensor placement, sensor sensitivity, units of measurement, and data interpretation. If you are not used to performing this type of testing, it is easy to make a mistake with your equipment or calculations. Incorrect settings, of course, can jeopardize your results. Third-party surveys give you reliable data that you can count on to make decisions.

An experienced engineering firm that specializes in site surveys can quickly understand when data is incorrect and fix it on-site. A third-party firm that regularly conducts site surveys will have accurately calibrated equipment and redundancies in place to ensure it collects accurate data.

Reason Three: Mistakes are Costly

If you overstate the vibration, acoustic noise, or magnetic fields in the data, it can result in the unnecessary spending of tens, if not hundreds of thousands of dollars. It can result in unnecessary work on retrofitting the room, mitigation equipment, and project delays.

Conversely, understating vibration, acoustic noise, and magnetic field levels can cause severe issues if left unaddressed. It can result in remediation efforts that occur too late in the process, causing costly tool performance problems. Some examples of costly mistakes include new tool movements, air handler system retrofit, or non-optimized mitigation equipment.

Reason Four: A Third-Party Site Survey Offers Detailed Recommendations

A third-party survey comes with the insight and the experience of the company that you hire. The engineers can help you to identify the sources of the problems identified in the site survey. They can offer detailed recommendations on how to mitigate common issues.

A third-party company can also offer professional-level and high-performing mitigation solutions that will allow you to fix any flagged issues in the least costly manner. VEC provides outside the box mitigation recommendations based on over 30 years of industry experience in similar situations.

Conclusion

A third-party site survey provider like VEC will give you the best possible information to make decisions regarding your facility. When you have better data, you can make more informed decisions and save money in the process. With a third-party site survey, you will not have to pay as much on capital expenditures while working to optimize tool performance.

If you have any additional questions on how a third-party engineering firm can help with site surveys and tool optimization, contact us today!