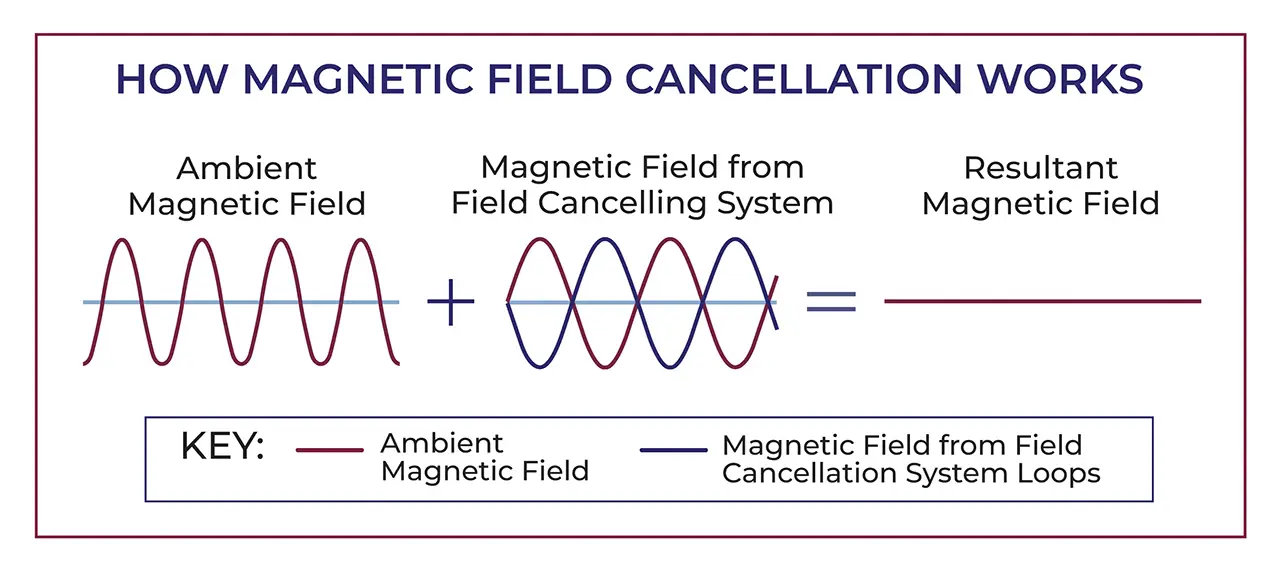

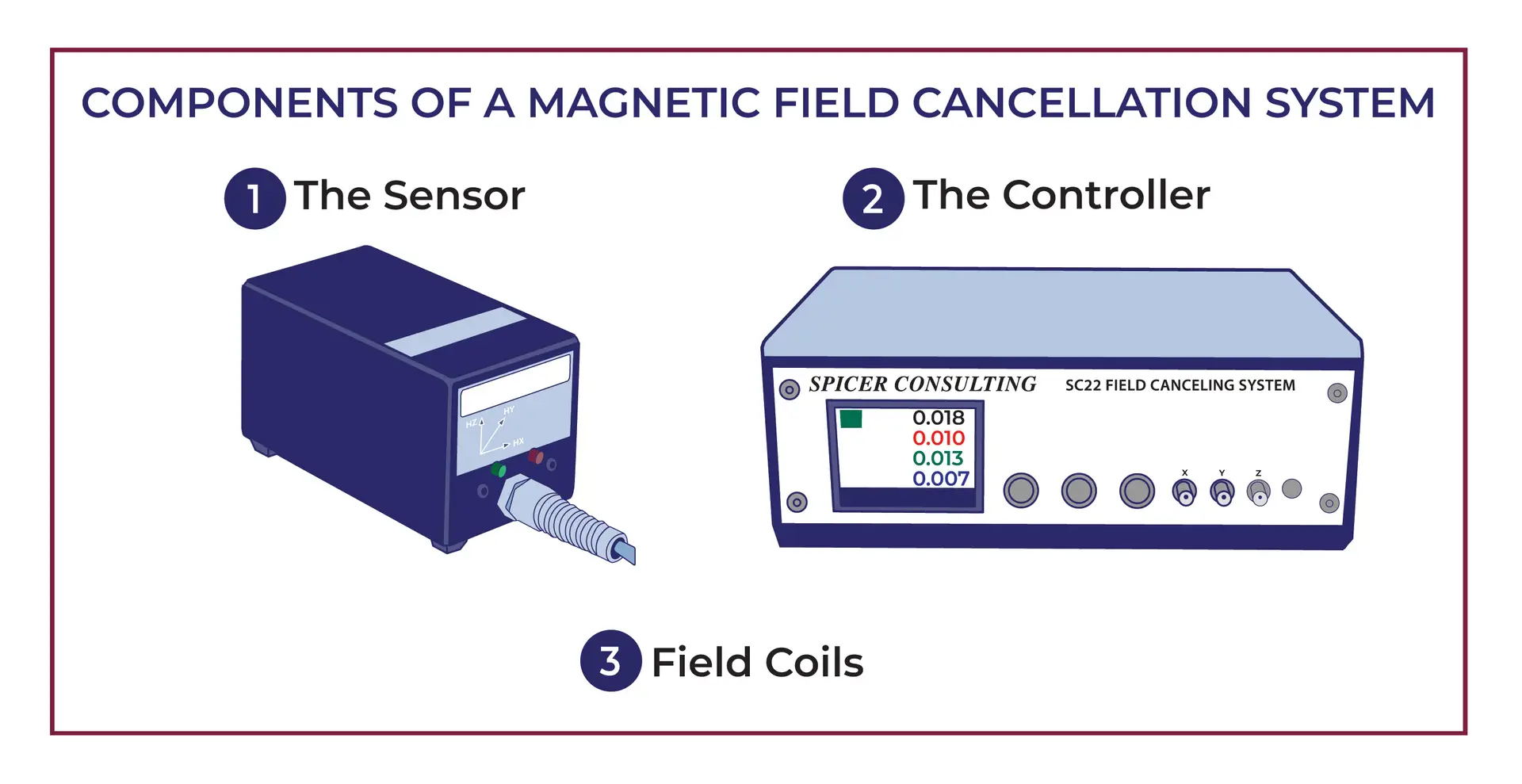

An EMI cancellation system cancels electromagnetic interference (EMI) that degrades electron microscopes performance. Using a sensor, controller, and field canceling loops, the EMI cancellation system measures the ambient magnetic field at the electron beam column and then generates an equal and opposite field thereby eliminates EMI that would otherwise cause interference on the image.

The type microscope, laboratory layout, magnetic field type, and adjacent tools all impact how EMI cancellation systems design. Our experts at VEC can design a system that will meet your custom needs.

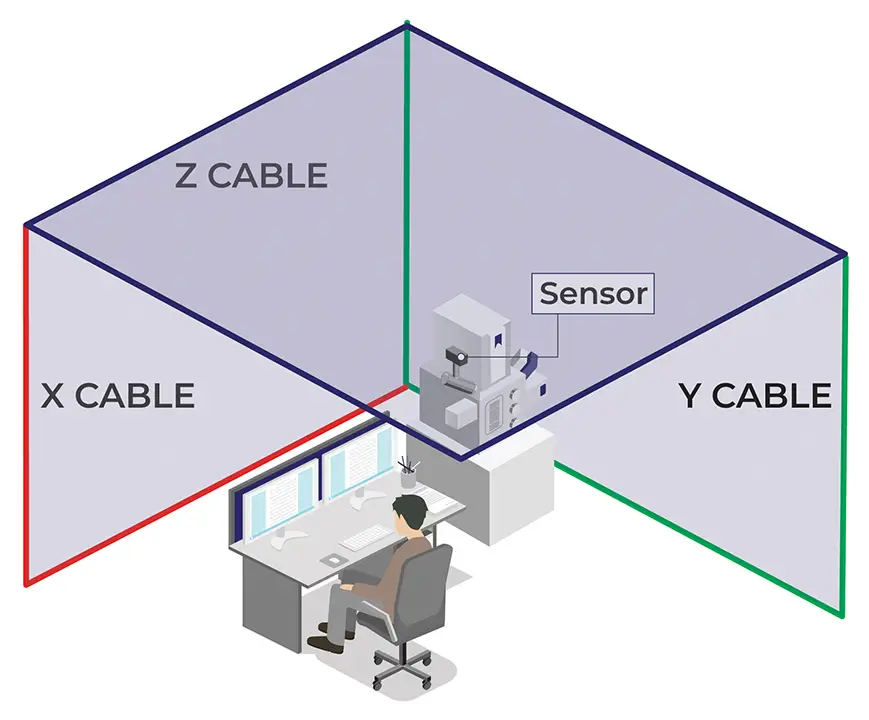

EMI cancellation systems detect the magnetic field at the location of your electron beam column or detector. Using precisely designed cable layout, EMI cancellation systems generate an equal and opposite field (180 degrees out of phase) to the ambient field in a room. These two fields – the ambient field and the field generated by the EMI cancellation system – cancel each other.

Several tool-related factors impact EMI cancellation. For instance, the length of the electron beam determines how susceptible it is to interference from external fields. The longer the electron beam path, the more uniformity in the field cancellation that is required.

The type of imaging that will be conducted by the tool also has an impact on EMI cancellation. For longer duration imaging, intermittent DC fields, such as elevators or the movement of large, ferromagnetic objects can result in images, or portions of data being rendered unusable. For shorter duration imaging, these intermittent disturbances might be less problematic because the image can be quickly retaken.

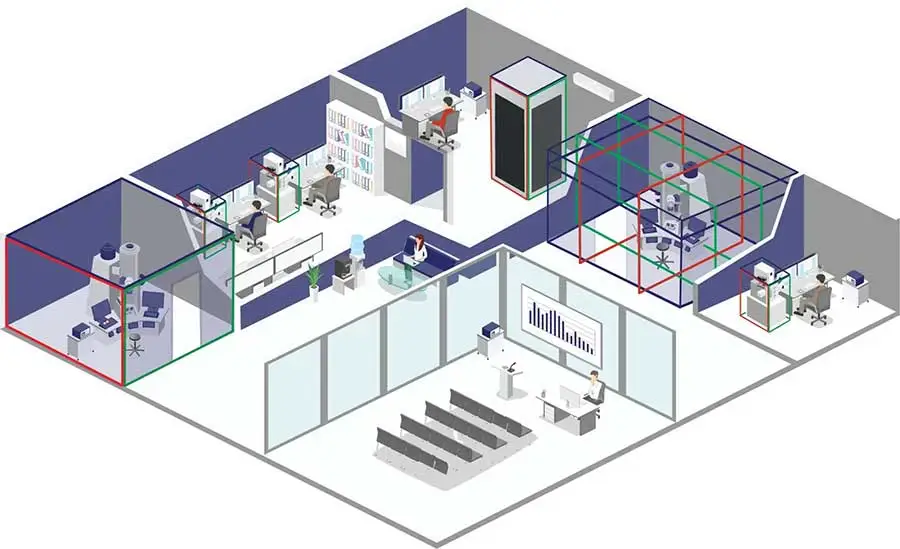

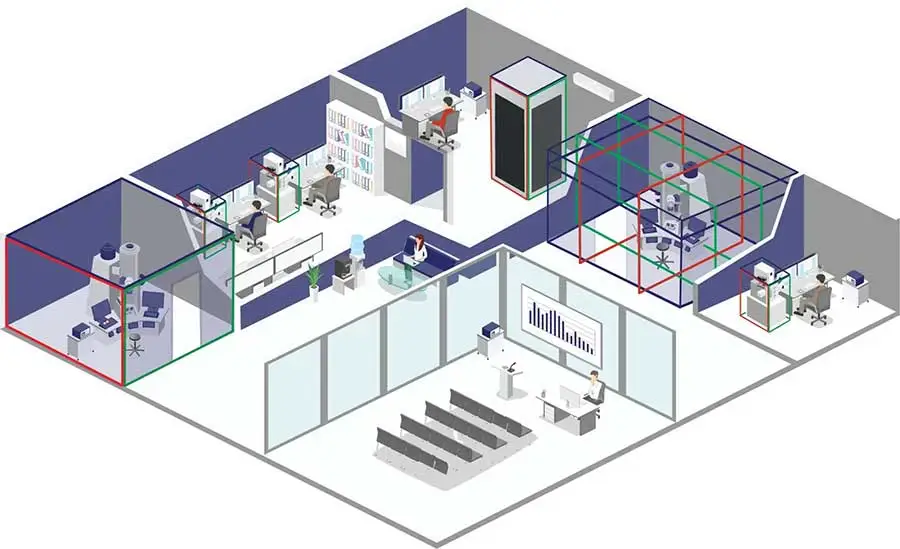

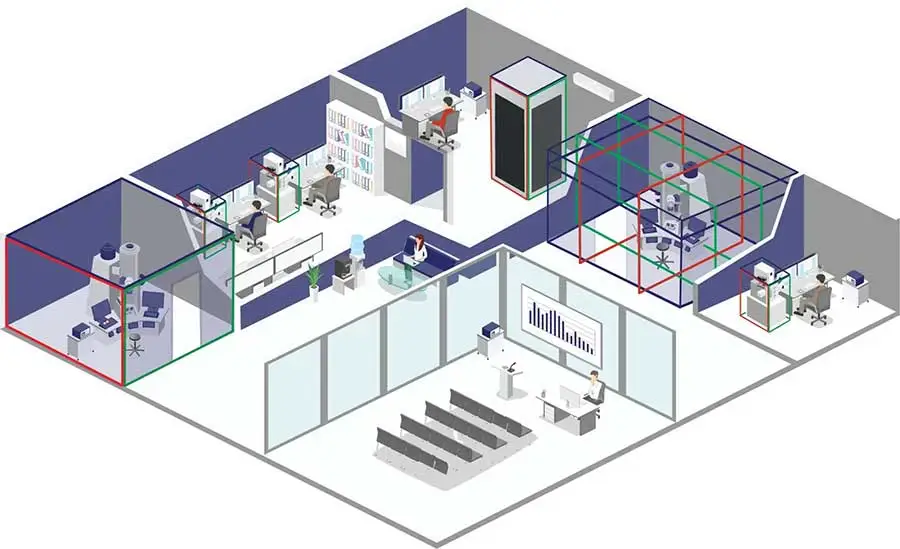

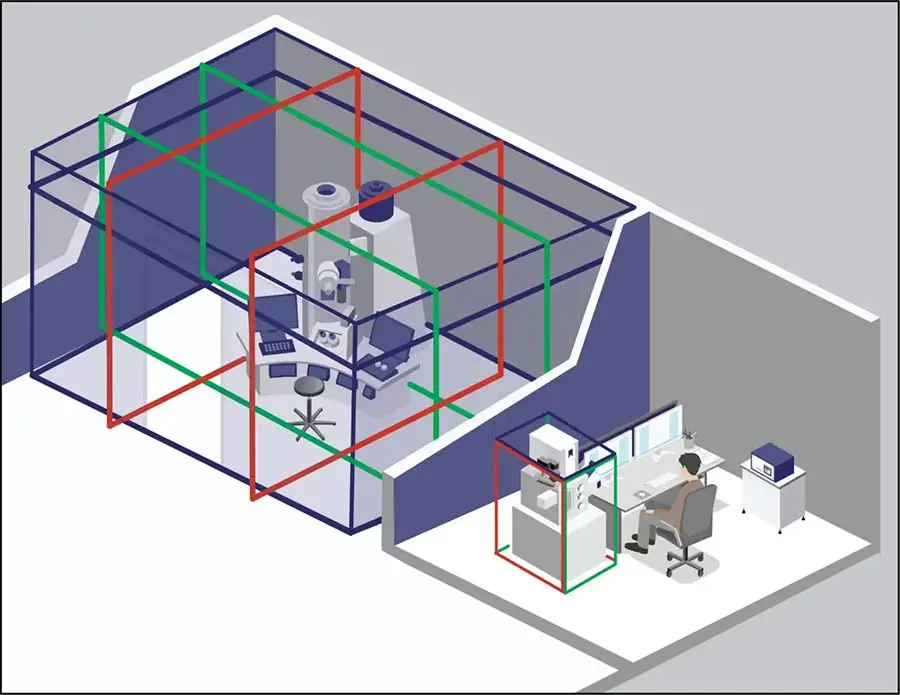

For the field cancellation system to work optimally, the electron microscope system or tool column should be in the center of the field cancellation loops. If the microscope is located in the center of the room, then room coils might be the best option. However, if the microscope is in a very large room, or a problematic location, alternative installations should be considered. Microscopes that have enclosures might be able to have the coils routed through the enclosure. This option works well for many microscopes or e-beam tools. A VEC engineer can discuss with you what that might mean for your individualized situation.

The type of magnetic field and field strength are critical when determining the optimal cancellation system. A change in the DC magnetic fields requires different sensors and a different controller an AC field would require.

The strength of the field is also important. VEC engineers model the layout of the cable system to optimize field cancellation along the electron beam-column. Modeling cancellation performance helps ensure that the system works for the magnitude and type of field impacting your microscope.

Because the field cancellation loops generate a magnetic field is cancel the ambient fields at your microscope, VEC must consider adjacent tools when designing an EMI cancellation system. Field cancellation systems in adjacent rooms can even interfere with each other or even oscillate.

Our engineers at VEC have many options to ensure that two or more magnetic field cancellation systems do not oscillate with each other or cause interference on adjacent microscopes. VEC will design and model the system to both guarantee performance and ensure that multiple systems will work in adjacent rooms and on tools in close proximity.

Installing EMI cancellation systems is a complex process, with multiple factors that can influence results. It helps to go with an engineering company that has more than 35 years of experience. VEC can design and install a magnetic field cancellation system based on your unique requirements.

If you have any questions or would like to discuss your organization’s unique situation, contact us today!

Contact our expert team at VEC to get started.