Understanding Vibration Isolation for Electron Microscopes and Precision Instruments

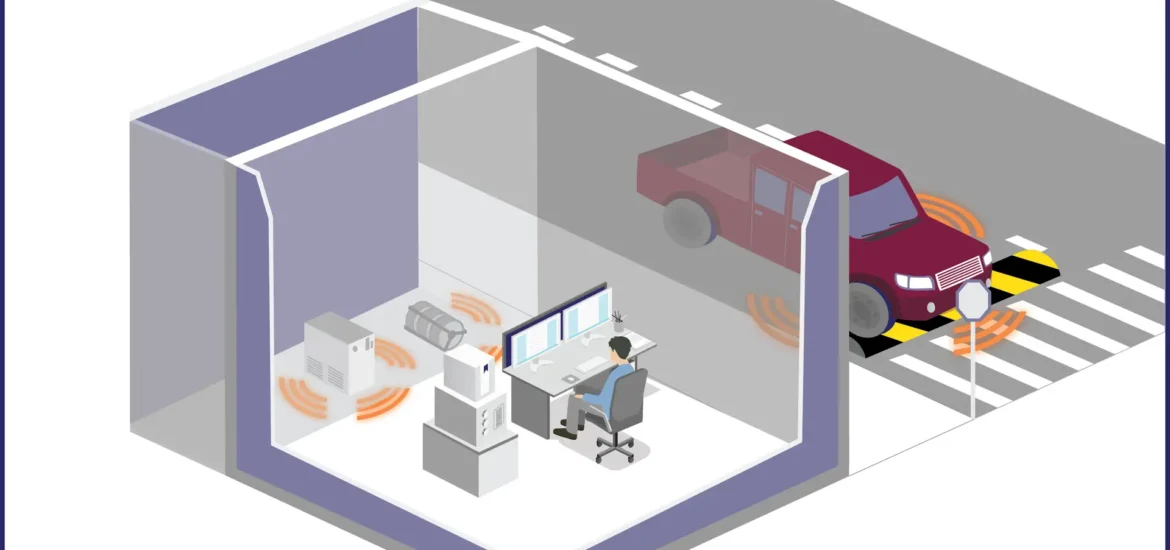

High-precision instruments such as electron microscopes are extremely sensitive to vibrations. Effective vibration isolation is crucial to ensuring optimal imaging performance and tool effectiveness. Many high-end systems come equipped with onboard passive vibration isolation platforms, yet there is still a need for active vibration isolation systems. This blog aims to clarify the distinction between these two systems and explain how they work together to provide a comprehensive vibration isolation solution for your instrument, regardless of your facility’s specific challenges.

Types of Vibrations That Impact Equipment

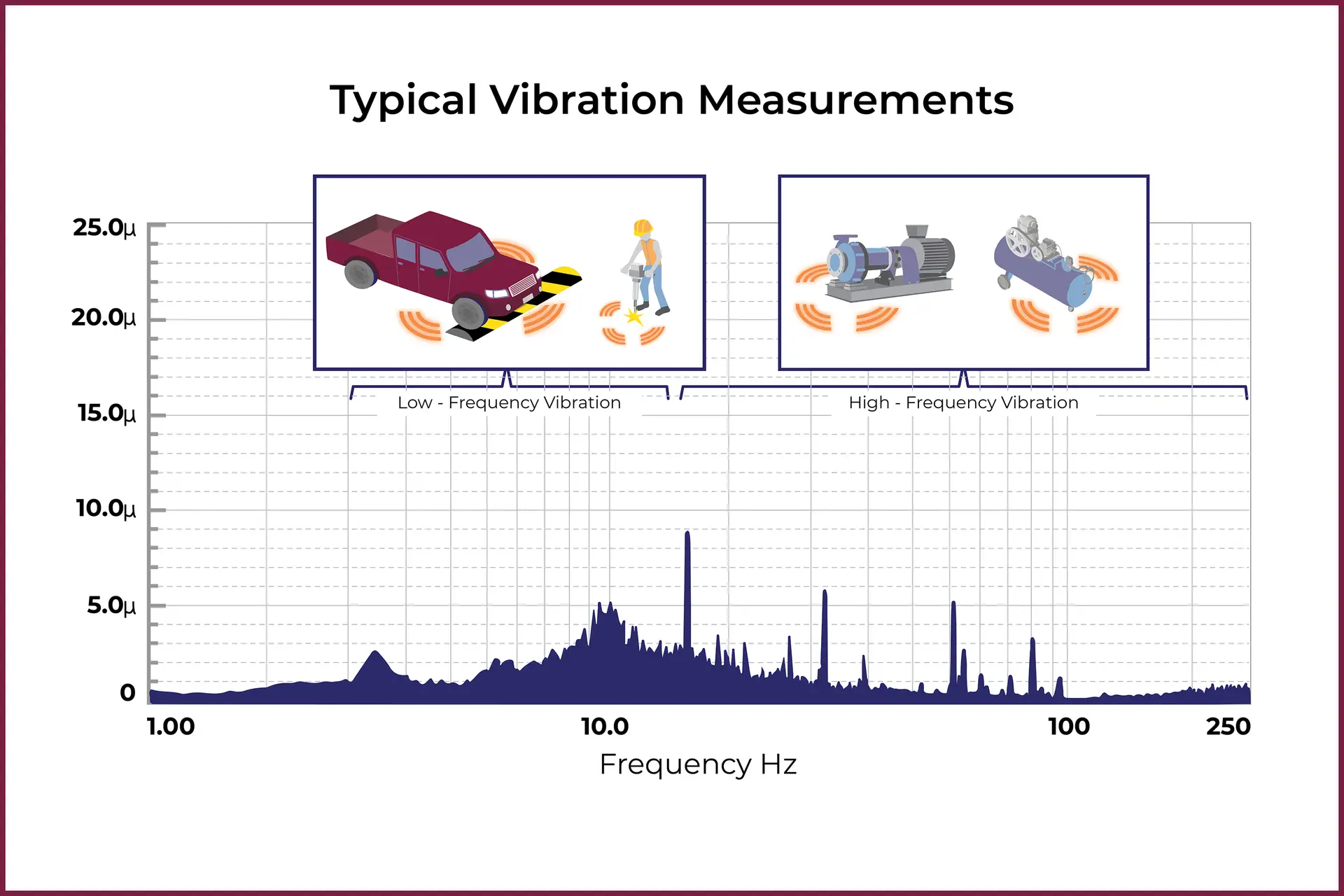

Two primary types of vibrations affect high-precision instruments:

1. Low-Frequency Vibrations

Typically caused by external excitations such as construction activity, truck traffic, and trains.

These excitations can stimulate ground and building resonances, leading to elevated vibration levels in the 3 to 15 Hz range.

Identified by broad resonant peaks on the Fast Fourier Transform chart

2. High-Frequency Vibrations

Primarily caused by rotating mechanical equipment such as motors.

These vibrations generally occur under 60 Hz due to motor slip in induction motors or at different frequencies due to onboard reduction gears and other mechanical components.

Identified by sharp peaks at the drive frequency of the equipment. These peaks can move when using variable frequency drives.

Since these two types of vibrations originate from different sources and impact equipment in distinct ways, employing a combination of passive and active vibration isolation systems is essential.

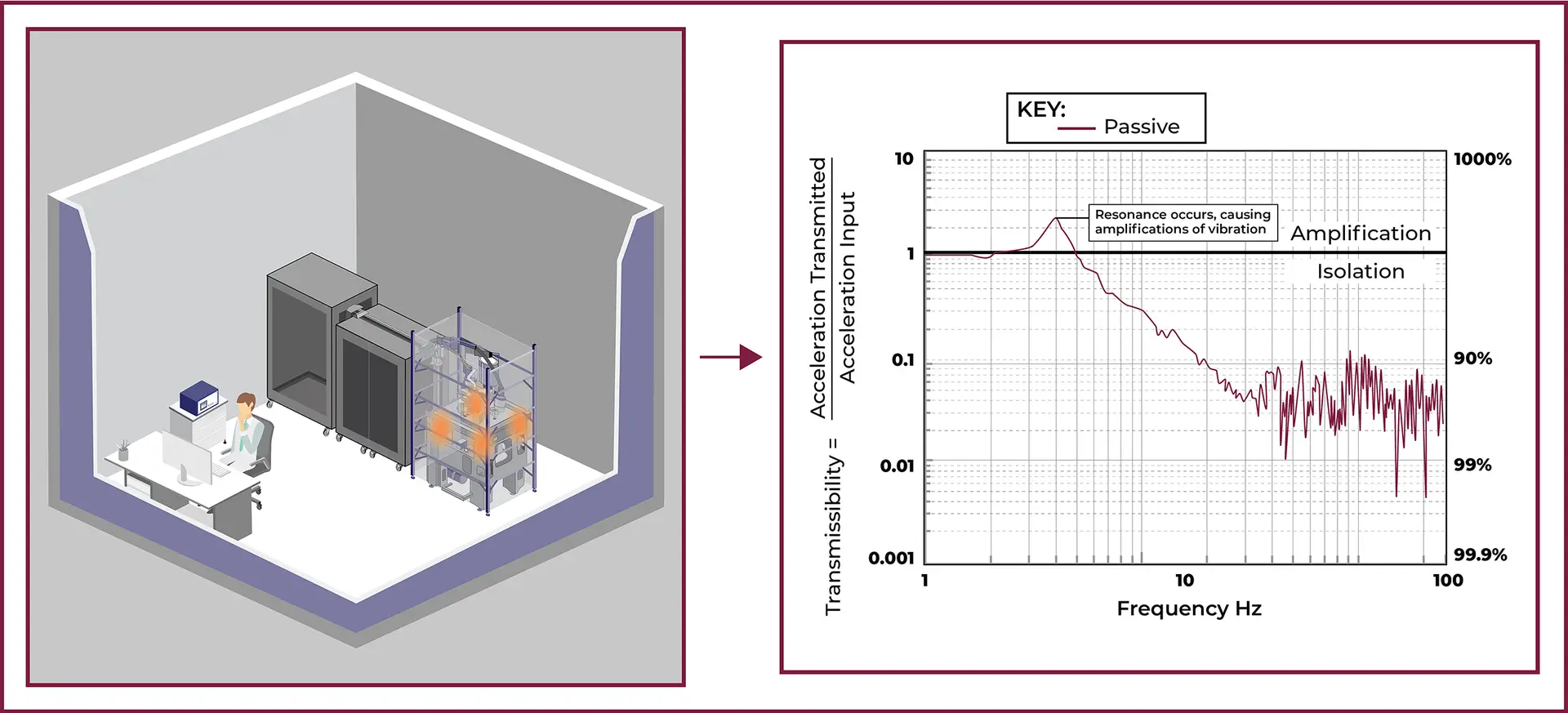

Passive Vibration Isolation Systems

Most high-precision instruments, including electron microscopes, feature onboard passive vibration isolation platforms. These systems are:

Passive and typically pneumatic (i.e., they do not have an active control loop to cancel out the vibration).

Highly effective at mitigating high-frequency vibrations from rotating equipment such as pumps and motors.

These systems have a natural frequency, meaning they amplify vibration at the natural frequency before rapidly attenuating higher-frequency vibration.

However, passive vibration isolation is less effective at mitigating low-frequency vibrations caused by ground resonances. In some cases, these systems may even amplify such vibrations if resonances correspond with the system’s natural frequency, creating the need for additional isolation strategies.

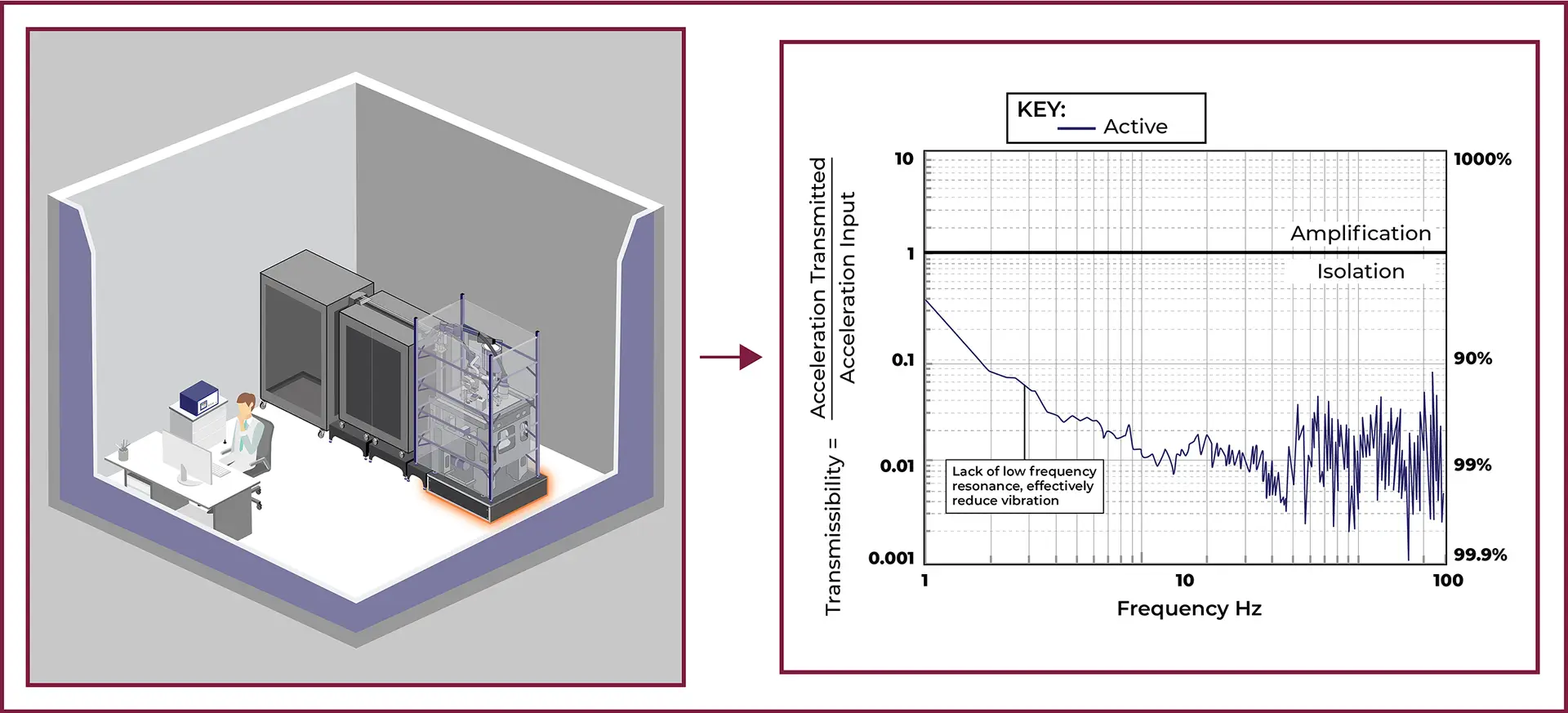

Active Vibration Isolation Systems

To address low-frequency vibrations, high-end active vibration isolation platforms—such as the VEC Daeil DVIA-M series—are used. These systems provide exceptional isolation performance beginning at sub 1 Hz and offer significant vibration reduction in the 3-15 Hz range, where ground resonances typically occur.

Key benefits of active vibration isolation platforms:

Offer 10X to 100X vibration reduction in the low-frequency range.

Effectively counteract vibrations before they reach the instrument.

Work in conjunction with passive systems to achieve comprehensive vibration isolation.

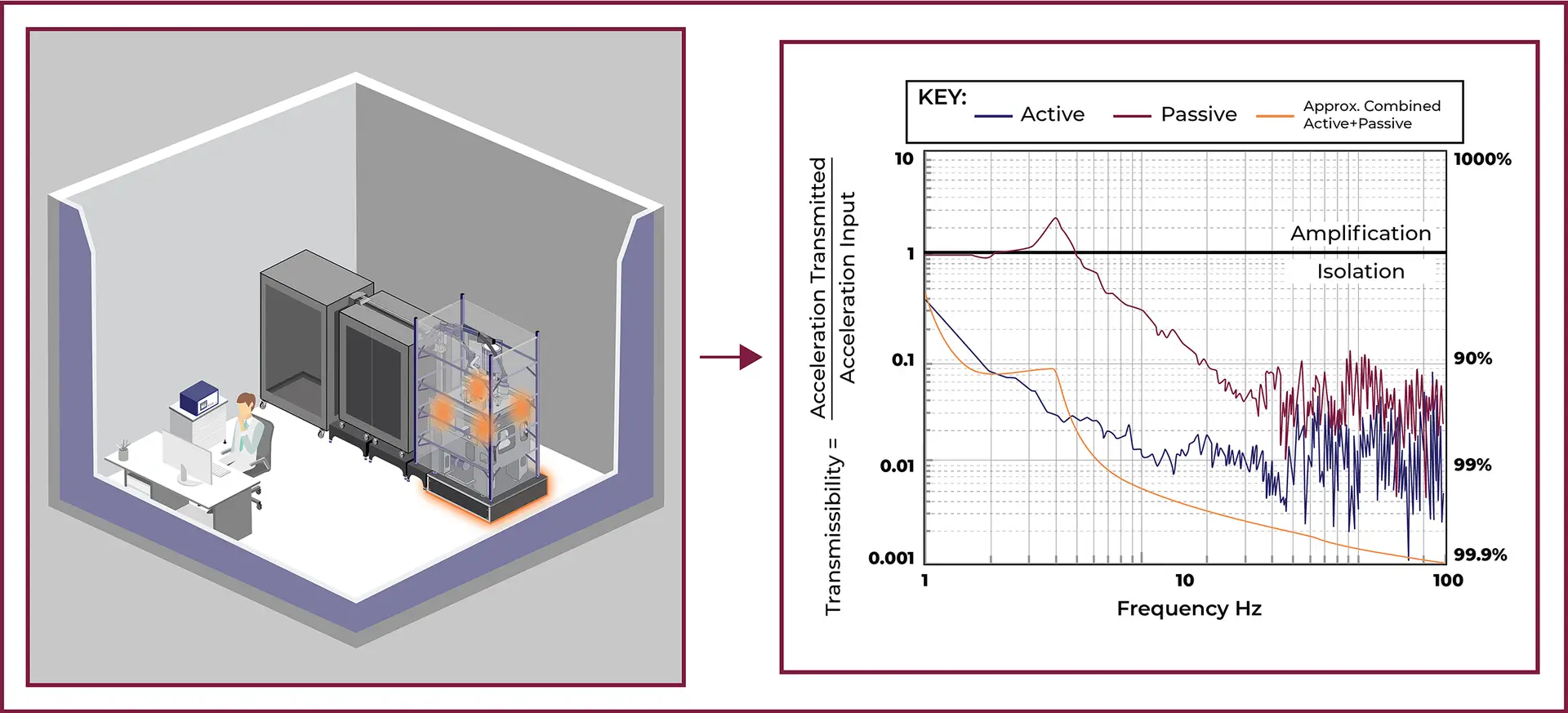

How Passive and Active Systems Work Together

While active vibration isolation platforms excel at mitigating low-frequency vibrations, they rely on the instrument’s onboard passive system to handle high-frequency vibrations from rotating equipment. Engineers can calculate the combined performance of both systems by multiplying their respective transmissibilities, which provides an overall vibration isolation effectiveness.

When paired with a high-performance active vibration isolation platform, a well-configured passive onboard isolation system for an electron microscope results in superior protection across the entire frequency spectrum. This setup ensures minimal external vibration impact on the instrument, leading to optimal performance for high-precision applications.

Conclusion

Understanding the interplay between passive and active vibration isolation systems is essential for maximizing the performance of electron microscopes and other sensitive instruments. While onboard passive systems effectively mitigate high-frequency vibrations, active vibration isolation platforms are crucial for counteracting low-frequency ground resonances. Combined, these two systems provide a comprehensive, high-performance vibration isolation solution, ensuring the highest level of precision in any environment.

Contact us to get started on your project. The VEC Team is ready to help find the best solutions for your investment.